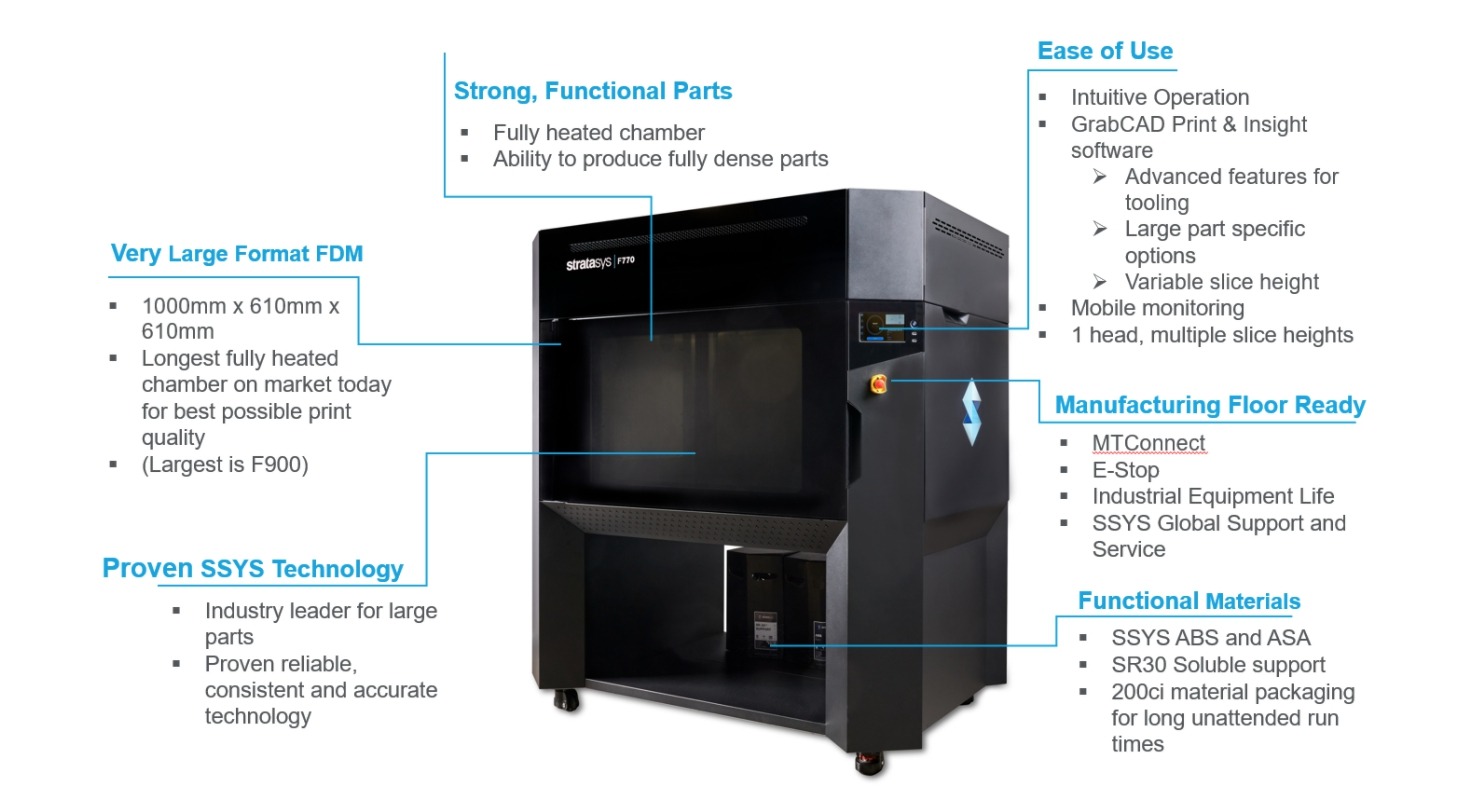

STRATASYS F770 All in one printer with the best performance

STRATASYS F770 3D printer, the best printer for large scale designs with the highest strength and industrial resolution that can reduce production costs

Jumbo size printing, Stratasys F770 is needed!

3D Printer from Stratasys, the leading FDM Technology ™

Stratasys F770 3D printer, the ultimate for the large scale design printing with high strength complex tasks and industrial resolution, fulfills Additive Manufacturing tasks to reduce production process costs.

Stratasys 3D Printer รุ่น F770 is a 3D printer that prints parts as large as 1,000 x 610 x 610 mm and yields volumes up to 13 cubic feet (372 liters). The printer is easy to use, accurate, and reliable using FDM technology.

F770 Make small work of big parts.

Highlights of the Stratasys F770

- Prints up to 1 meter wide.

- The most significant volume is 372 liters.

- Continuous printing up to 140 hours.

- High resolution.

- Having ABS-M30 and ASA material.

- Soluble support, even complex tasks are easy to unpack.

- Easily print straight from your CAD files with GrabCAD Print™ software.

- Customize files before printing with Insight™ software.

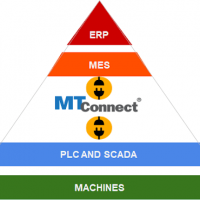

- Connect Smart Factory with MTConnect.

Stratasys F770™ Overview

F770 Applications

Large or Small design, just printing via F770

Jigs and Fixtures

large tools for production process

Prototyping

Create large prototypes

End-Use Parts

Print real parts for immediate use, both small and large

F770 Materials

The F770 3D printer uses ABS-M30 (Acrylonitrile Butadiene Styrene) and ASA (Acrylonitrile Styrene Acrylate) standard thermoplastics as the most widely used materials. Best suited for making large pieces, jigs and lightweight fixtures, including creating End-Used Parts

ABS-M30

A strong and durable thermoplastic. Suitable for a wide range of 3D printing applications

ASA

Similar to ABS, but has UV protection properties, making the parts not yellow and has a smoother surface

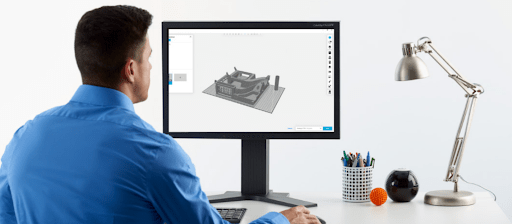

From CAD to Reality

GrabCAD Print ™ software accelerates workflows by directly opening CAD source files such as SOLIDWORKS, Catia, NX, Creo, Solid Edge, Inventor, IGES, STEP, etc. Parasolid files without user intervention. Convert files to the original STL extension to be confident that what you design in CAD is what comes out of the printer.

F770 Delivers

Large print capacity.

Large area to print parts up to 1 meter long

Stratasys FDM reliability.

Additive Manufacturing technology from Stratasys has earned users’ trust and is the leader in the 3D Printer market

Simple, no-hassle operation.

GrabCAD Print Software an easy-to-use, hassle-free 3D printing software that allows users to open CAD source files directly

The F770 Complexity without complications.

Size isn’t the only outstanding feature of the F770. Stratasys provides GrabCAD Print software that allows you to do CAD-to-Print. For better printing results, the F770 can operate 24/7 without needing to constantly check the printer while printing, and the F770 has a built-in camera that lets you update your print status. The F770 also has MTConnect ready to efficiently connect to your Smart Factory system.

13 cu ft (372 liters) build volume

GrabCAD Print and Insight software

MTConnect ready

Reliable large-scale printing in a user-friendly,

affordable system.

Key Attributes : F770

Compare the F770 to other FDM Printers.

F770 (*New)

- Tray size and build plate shape :

1,000 x 610 x 610 mm - Materials : 2

- Cartridge capacity : Up to 200 cu in

- Tray size and build plate shape :

355 x 254 x 355 mm - Materials : 8

- Cartridge capacity : Up to 90 cu in

- Tray size and build plate shape :

914 x 610 x 914 mm - Materials : 16

- Cartridge capacity : Up to 500 cu in

- Tray sizeand build plate shape :

254 x 254 x 254 mm - Materials : 2

- Cartridge capacity : 200 cu in.

- Tray sizeand build plate shape :

254 x 254 x 254 mm - Materials : 6

- Cartridge capacity : 90 cu in.

- Tray sizeand build plate shape :

305 x 254 x 305 mm - Materials : 6

- Cartridge capacity : Up to 90 cu in.

A Customer’s View of the F770

“Big is always good – you can make small parts in a big machine but you can’t make big parts in a small machine.”

Philipp Goetz

Doug Steindl, corporate development lab supervisor at Sub-Zero Group

Sample work

Read more : STRATASYS