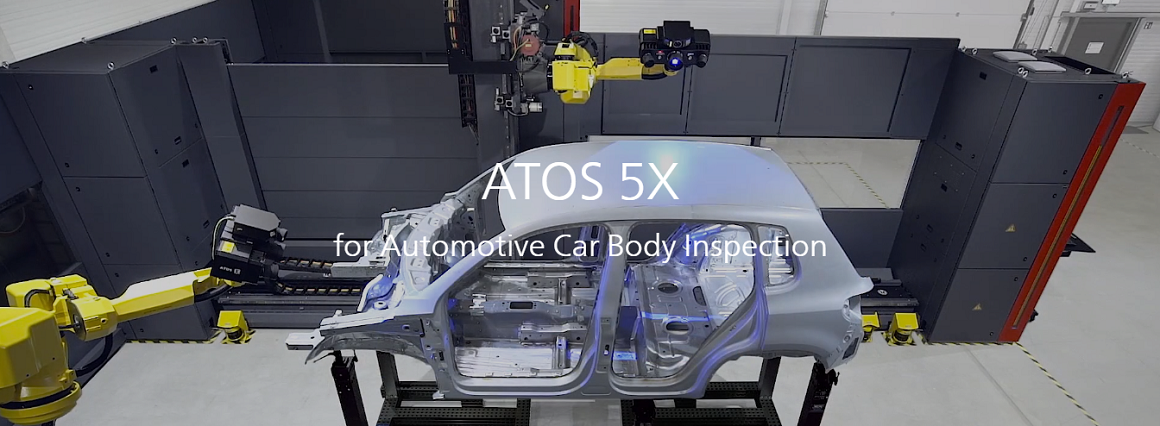

ATOS 5X

เทคโนโลยีที่ใช้ในระบบการวัดอัตโนมัติสำหรับการสแกนชิ้นงานที่มีขนาดใหญ่ มาพร้อมแหล่งกำเนิดแสงอันทรงพลังของ ช่วยให้สามารถตรวจวัดชิ้นงานขนาดใหญ่ ด้วยความเร็วสูงสุด

ที่สุดของความเร็ว ความละเอียด แม่นยำในทุกงานสแกน

ATOS 5X สำหรับการตรวจวัดตัวถังรถยนต์

ATOS 5X สแกนชิ้นงาน เทคโนโลยีที่ใช้ในระบบการวัดอัตโนมัติสำหรับการสแกนชิ้นงานที่มีขนาดใหญ่ ที่มาพร้อมแหล่งกำเนิดแสงอันทรงพลังของ ช่วยให้สามารถตรวจวัดชิ้นงานขนาดใหญ่ ด้วยความเร็วสูงสุด เหมาะสำหรับงานอุตสาหกรรมที่ต้องอาศัยความรวดเร็ว และแม่นยำในการตรวจสอบ โดยใช้งานร่วมกับ ATOS ScanBox จะทำให้ ATOS รุ่นนี้ เป็นระบบสแกนระดับ High-End ช่วยเพิ่มประสิทธิภาพการออกแบบและกระบวนการผลิตได้

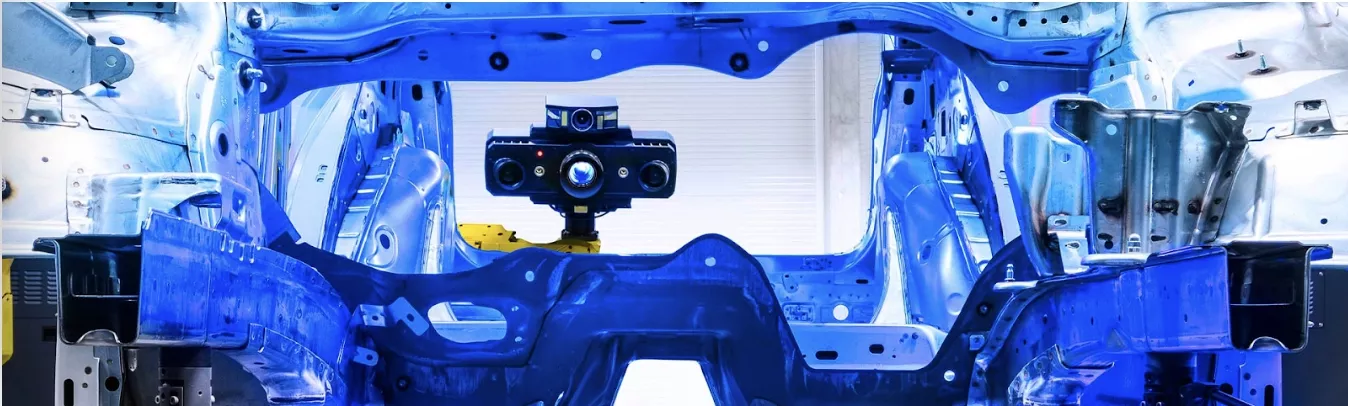

Blue Light Equalizer & Laser Light Compressor เทคโนโลยีการตรวจวัดความเร็วสูง

ใช้ Laser Light Compressor มาเป็นแหล่งกำเนิดแสงสีน้ำเงินที่มีความสว่างเป็นพิเศษและให้ความคมชัดสูงมากยิ่งขึ้น ช่วยให้สามารถวัดพื้นที่ได้สูงถึง 1,000 มม. ในขณะเดียวกันก็ใช้เวลาในการเปิดรับแสงที่สั้นมาก โดยใช้เวลาในการสแกนต่อครั้งใช้เพียง 0.2 วินาที

คุณสมบัติของ Blue Light Equalizer

- ครอบคลุมรูปทรงที่ต้องการได้อย่างแม่นยำ

- การทำสำเนาที่มีรายละเอียดสูง

- การรบกวนของแสงต่ำ-ครอบคลุมรูปทรงที่ซับซ้อนได้อย่างแม่นยำ

รวดเร็ว แม่นยำ คุณภาพข้อมูลสูงสุด

เทคโนโลยีระบบการวัดด้วยแสงแบบ 3 มิติ สามารถสแกนชิ้นงานได้อย่างรวดเร็ว ได้ข้อมูลที่มีคุณภาพ ง่ายต่อการตรวจสอบชิ้นงาน สามารถใส่ค่าเบี่ยงเบนให้อัตโนมัติระหว่างงานสแกนกับ3D CAD นอกเหนือจากนี้ยังมีซอฟต์แวร์ที่ช่วยระบุค่า GD&T การตรวจวัดขอบตัด(Trimming) หรือตำแหน่งรู และอื่นๆ ได้แบบอัตโนมัติ

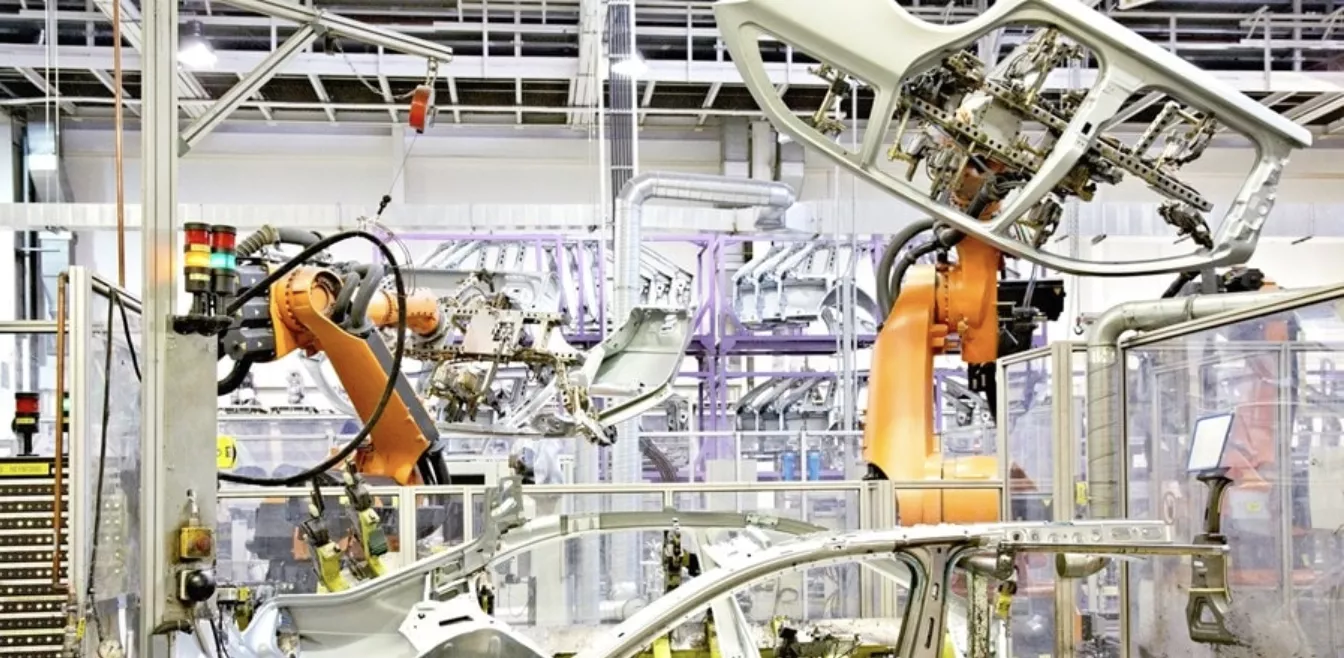

ระบบการวัดของ GOM ช่วยให้ท่านมั่นใจในคุณภาพ สามารถใช้งานได้ในทุกอุตสาหกรรม ไม่ว่าจะเป็น ผลิตภัณฑ์โลหะแผ่น งานหล่อ และพลาสติกในอุตสาหกรรมยานยนต์ การบินและอวกาศ หรือสินค้าอุปโภคบริโภค ซึ่งสิ่งเหล่านี้เป็นข้อมูลสำคัญในการเพิ่มประสิทธิภาพการผลิต

ความแม่นยำด้วยนวัตกรรม

ATOS 5 พัฒนาขึ้นสำหรับใช้ในอุตสาหกรรม โดยสามารถส่งข้อมูลที่มีความแม่นยำสูงในเวลาการวัดที่สั้นแม้ในสภาวะที่ไม่เอื้ออำนวย ข้อมูลการวัด 3 มิติ จะช่วยให้ท่านสามารถควบคุมกระบวนการทำงานและควบคุมคุณภาพได้ นอกจากนี้ยังแสดงภาพข้อผิดพลาดได้ ช่วยให้ผลิตเร็วขึ้น

กระบวนการที่รวดเร็วและเชื่อถือได้

สแกนเนอร์ 3 มิติ ATOS 5 และ ATOS 5X ทั้งสองเครื่องใช้เทคโนโลยีระบบการวัดด้วยแสงแบบ 3 มิติ ที่มีความละเอียดสูง มีความน่าเชื่อถือ ด้วยเทคโนโลยีดังกล่าวช่วยให้สามารถวัดพื้นผิวมันวาว โครงสร้างที่มีละเอียดซับซ้อน และขอบชิ้นงานได้ดี

ข้อมูลทางเทคนิค (เครื่องสแกนเนอร์ ATOS 5)

| ATOS 5 for Airfoil | ATOS 5 | ATOS 5X | |

| Light source | LED | LED | Laser |

| Laser class | - | - | 2/3B * |

| Points per scan | 12 million | 12 or 8 million | 12 million |

| Weight | approx. 14 kg | approx. 14 kg | approx. 14 kg |

| Dimensions | approx. 550 mm x 320 mm x 200 mm | ||

| Housing | dustproof, splashproof | ||

| Cable length | fiber optic cable up to 30 m | ||

| Operating system | Windows 10 | ||

| Measuring volumes | 100,170,270,400 | 170,320,500,700, 1000 | 320,500,700,1000 |

| Measuring area [mm²] | 100 × 70 – 400 × 300 | 170 × 140 – 1000 × 800 | 320×250 – 1000× 800 |

| Point distance[mm] | 0.03 – 0.1 | 0.05 – 0.25 | 0.08 – 0.25 |

| Camera angle | 27.5° | 27.5° | 27.5° |

| Working distance [mm] | 530 | 880 | 880 |

* อ้างอิงตามมาตรฐาน IEC 60825-1: In 2014, classified as a Class 2 laser in automated use and as a Class 3B laser in manual use (safety distance without safety goggles > 700 mm).