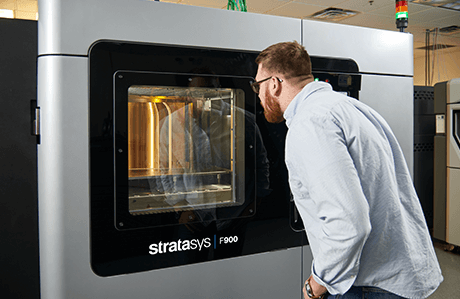

Stratasys F900

The largest-capacity FDM printer.

Work Big

The Stratasys F900 is built specifically for manufacturing and heavy industries, where you plan and work big. With the largest build size of any FDM system, it’s designed to handle the most demanding manufacturing needs.

Achieve faster build time for large parts by adding the Acceleration Kit to your printing system and scale up production quickly.

Enhanced efficiency and visualization for your part designs by directly importing the most commonly used CAD file formats into GrabCAD Print.

Production phase optimization with Insight Software lets you change your designs on the fly, revise production materials, and more, all without delaying your overall production schedule.

Automated production and monitoring capability with MTConnect-readiness with remote internal cameras, dew point monitor, dual material bays and high-capacity material options.

Fewer production system breakdowns because the printing system is built with many of the same standard, engineering-grade and high-performance thermoplastics used in traditional manufacturing processes.

F900 PRO

The F900 PRO is an upgrade option to the F900, delivering superior material properties and the lowest part-to-part variance when using ULTEM™ 9085 resin material. The F900 PRO employs hardware and process differentiators relative to standard F900 systems, to enhance repeatability, part performance and yield.

Versatility and Performance

Build robust production parts, jigs, fixtures, factory tooling and functional prototypes with the Stratasys F900. It uses a wide range of thermoplastics with advanced mechanical properties so your parts can endure high heat, caustic chemicals, sterilization and high-impact applications.

For more details on the specific materials handled by the Stratasys F900, refer to FDM Thermoplastics.

F900 PRO

The F900 PRO is an upgrade option exclusively for use with ULTEM™ 9085 resin material. It offers unparalleled performance for manufacturers needing superior part properties and the lowest production variance with this material.

Specifications

SYSTEM SIZE AND WEIGHT : 2772 x 1683 x 2027 mm (109.1 x 66.3 x 78.1 in); 2869 kg (6325 lbs.)

With Manufacturing Light Tower: 2772 x 1683 x 2281 mm (109.1 x 66.3 x 89.8 in.)

BUILD SIZE : 914.4 x 609.6 x 914.4 mm (36 x 24 x 36 in)

Platen supports two build zones for either small or large build sheets.

LAYER THICKNESS

- 0.508 mm (0.020 in): ASA, ULTEM™ 1010 resin

- 0.330 mm (0.013 in): ASA, ABS (M30, M30i), PC (all types), ULTEM™ resin (all types), FDM (all types), FDM Nylon 12CF, ST-130

- 0.254 mm (0.010 in): ASA, ABS (all types), PC (all types), ULTEM™ resin (all types), PPSF, FDM (all types)

- 0.178 mm (0.007 in): ASA, ABS (all types), PC (all types), FDM Nylon 12

- 0.127 mm (0.005 in): ASA

ACCURACY : Parts are produced within an accuracy of +/- .089 mm or +/- .0015 mm per mm (+/- .0035 in. or +/-.0015 in. per in.), whichever is greater.

Z part accuracy includes an additional tolerance of +/- 0.000 mm slice height.

Note: Accuracy is geometry-dependent. Achievable accuracy specification is derived from statistical data at 95% dimensional yield. See the Fortus 900mc accuracy white paper for more information.

*See Fortus 900mc Site Prep Guide for detailed power and environmental specs.

Smarter Software

The Stratasys F900 comes with GrabCAD Print and Insight Software that make it easier for you to manage and control your printing projects.

- GrabCAD Print makes it easy to print directly from your favorite professional CAD formats, comes loaded with default settings, tooltips and notifications to guide you through the printing process, and gives you detailed views of your models, trays and slice previews.

- Insight Software helps you fine-tune part performance and material use so you can produce your parts more efficiently. It lets your design, engineering and manufacturing teams collaborate more as they network and share 3D manufacturing capacity to maximize efficiency and throughput.