ATOS Capsule

ATOS Capsule – ATOS Capsule is an optical precision measuring machine (OPMM) for a full-field digitization of contoured part geometries

ATOS Capsule : Quality control with highest resolution

ATOS Capsule is an optical precision measuring machine (OPMM) for a full-field digitization of contoured part geometries.The fringe projection system of the ATOS series is used for production quality assurance of small to medium-sized parts like gears or turbine blades and excels by its high precision when scanning fine details.

Now Available

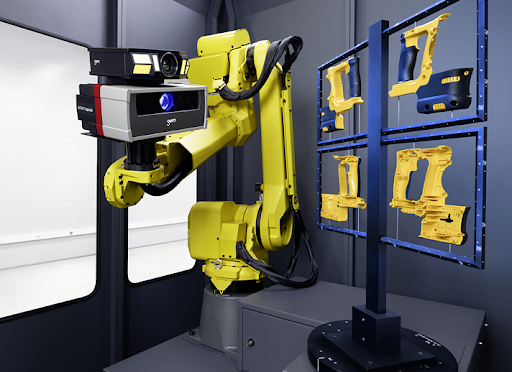

ATOS Capsule is now available in two versions with different levels of detail, and captures 8 or 12 million points per scan. The interchangeable measuring areas for this sensor cover different component sizes. Due to this flexibility, the system has been successfully used for years in the acquisition and inspection of contoured component geometries of small to medium-sized components. Thanks to its housing design, it offers outstanding process stability for automated applications in quality assurance during series production.

3D coordinate measurement High-end scanning and inspection system

Quality control with highest resolution

Technology

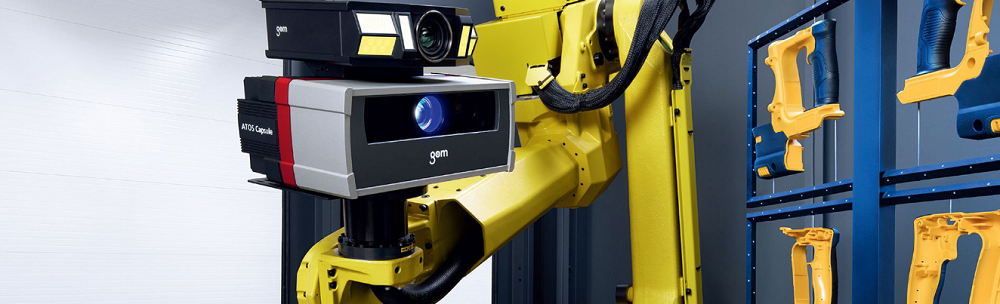

Due to its housing design, provides process stability for automated applications. Made of aluminum investment casting, the precisely manufactured unibody housing ensures maximum stiffness and precise measuring results for industrial use. Optics and electronics are protected against dust and splashing water.

Changeable Measuring Areas

MV40, MV70, MV120, MV200, MV320

Sensor Models

- 8 million points per scan

- 12 million points per scan

Technology Highlights

- Unibody housing

- Protected optics

- Protected electronics

- Industrial connectivity

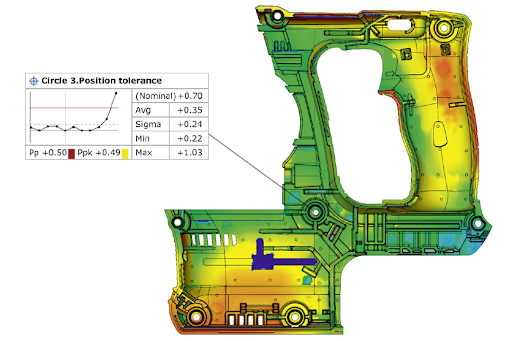

Parametric inspection

From CAD import to reporting, the ATOS Professional evaluation software provides all necessary tools for a comprehensive analysis of parts and components. Using parametric inspection, all actions and evaluation steps are completely traceable and interlinked. Thus, changes and modifications are possible at any time.

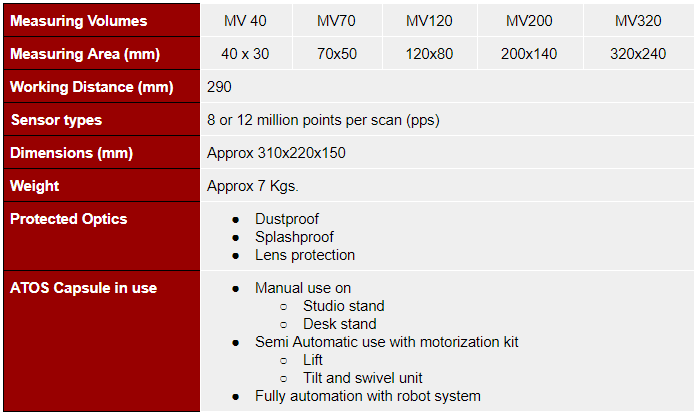

Technical Data