ATOS 5 สำหรับ Airfoil

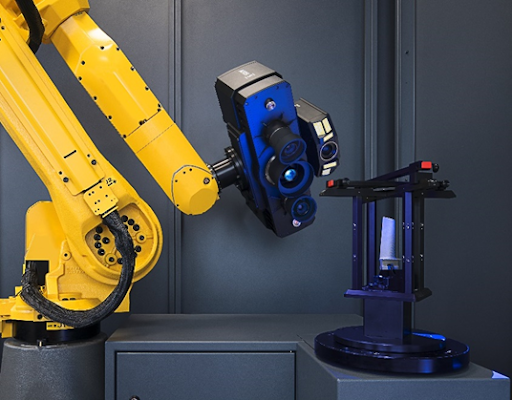

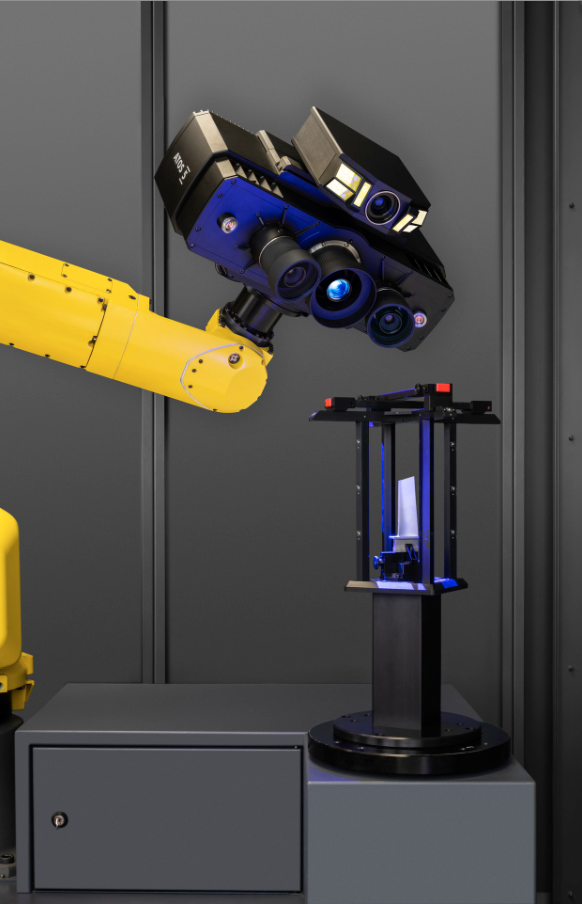

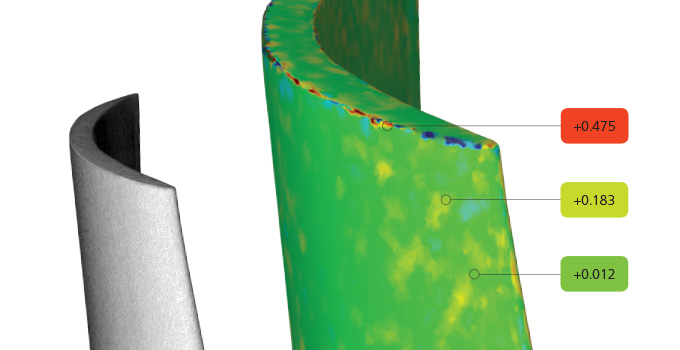

ATOS 5 สำหรับ Airfoil – การสแกนที่แม่นยำสำหรับชิ้นงานที่เล็กสุดสุด มีระโฟกัสที่ใกล้ ทำให้สามารถสแกนชิ้นงานขนาดเล็กๆได้ดี ได้ข้อมูลการสแกนแบบ 3D ที่ละเอียดและ แม่นยำสูง

ATOS 5 สำหรับ Airfoil

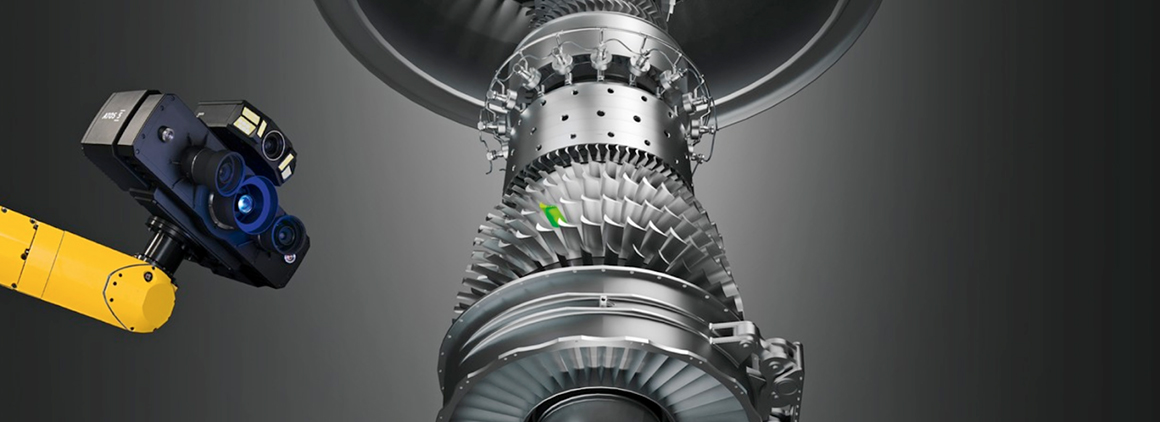

ออกแบบมาสำหรับอุตสาหกรรม Gas-Turbine โดยเฉพาะ

ATOS 5 สำหรับ Airfoil ถูกพัฒนาขึ้นมาอุตสาหกรรม Turbine Gas โดยเฉพาะ โดยกำหนดพื้นที่การวัดตั้งแต่ 100 x 70 mm² ถึง 400 × 300 mm² มีระโฟกัสที่ใกล้ ทำให้สามารถสแกนชิ้นงานขนาดเล็กๆได้ดี ได้ข้อมูลการสแกนแบบ 3D ที่ละเอียดและ แม่นยำสูง

ATOS 5 สำหรับ Airfoil การสแกนที่แม่นยำสำหรับชิ้นงานที่เล็กสุดสุด

- ระยะการสแกนที่มีโฟกัสใกล้กับชิ้นงาน

- มีความเสถียรสูงมากในการใช้งานอัตโนมัติ

- ประมวลผลเร็ว

- เวลาในการเปิดรูรับแสงสั้น

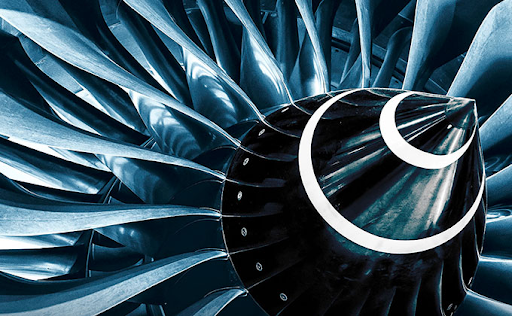

Fan Blade Inspection

การตรวจสอบใบพัดมีลักษณะเฉพาะ มีความซับซ้อนสูง และต้องใช้วิธีการทางเทคโนโลยีขั้นสูงเพื่อให้เป็นไปตามการทดสอบการทำงานและวัสดุ

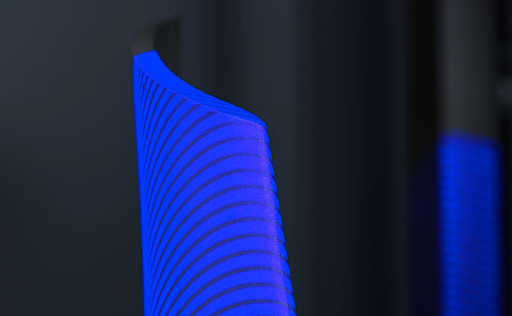

Turbine Blade Inspection

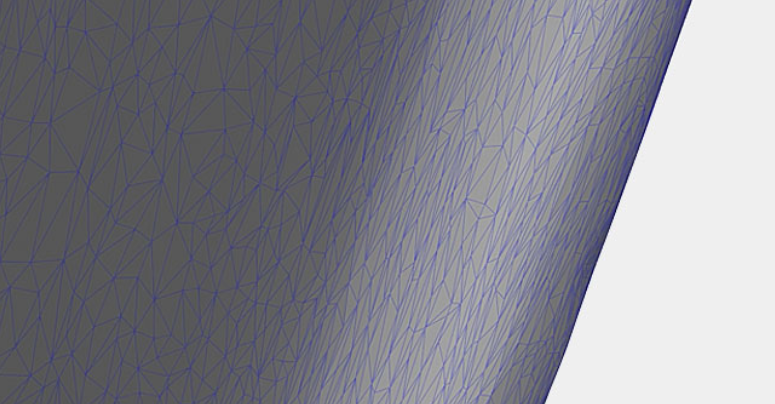

รายละเอียดที่เล็กที่สุดของใบพัด ซึ่งส่งผลกระทบต่อประสิทธิภาพและการสิ้นเปลืองเชื้อเพลิงของเครื่องบิน ดังนั้นความเร็วและความแม่นยำในการสแกน จึงเป็น หัวใจสำคัญในการทำงาน

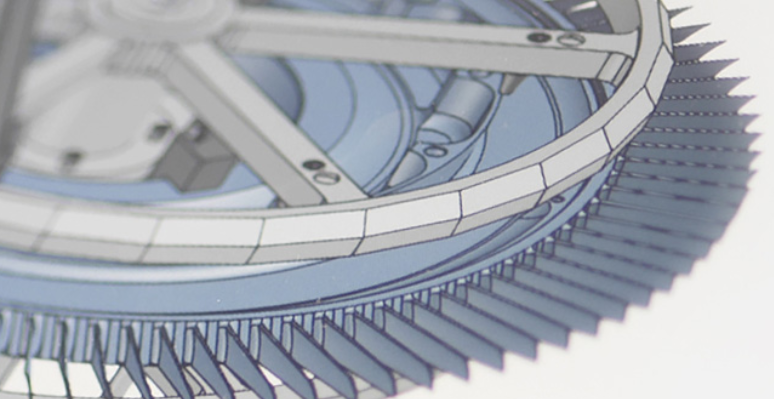

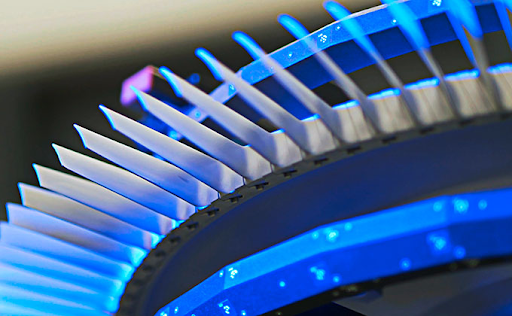

Blisk Inspection

การตรวจวัดใบพัดที่ประกอบเข้าด้วยกันแล้ว (Blisk) โดยสามารถใช้การสแกนด้วยระบบอัตโนมัติระดับไฮเอนด์เพื่อผลการตรวจสอบที่รวดเร็วและสามารถวิเคราะห์ข้อมูลเชิงลึกได้

Atos 5 For Airfoil Technology

- ATOS 5 สำหรับ Airfoil เครื่องสแกนชิ้นงาน 3 มิติ ระดับอุตสาหกรรม มาพร้อมเทคโนโลยีการตรวจวัดที่เร็วที่สุด

Blue Light Equalizer

- เทคโนโลยีนี้ ช่วยขจัดปัญหาในการวัดชิ้นงานที่เกิดจากแสงที่ไม่สม่ำเสมอ แสงของสภาพแวดล้อมที่มักมีการเปลี่ยนแปลงอย่างรวดเร็ว

Robust sensor design

- ถูกออกแบบมาเพื่อให้มีความแม่นยำสูงในงานสแกน ถึงแม้อยู่ในสภาพแวดล้อมที่เลวร้ายก็ตาม

Optimized working distance

- ถึงแม้รายละเอียดของชิ้นที่ต้องการสแกนจะมีขนาดเล็กมาก เครื่องก็สามารถสแกนและให้ข้อมูลมีคุณภาพสูงที่สุดได้

Unique software functionalities

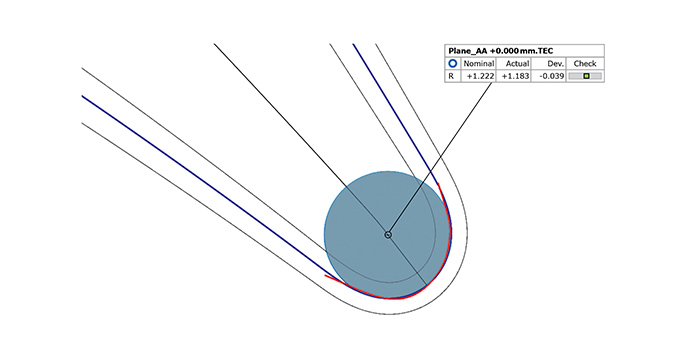

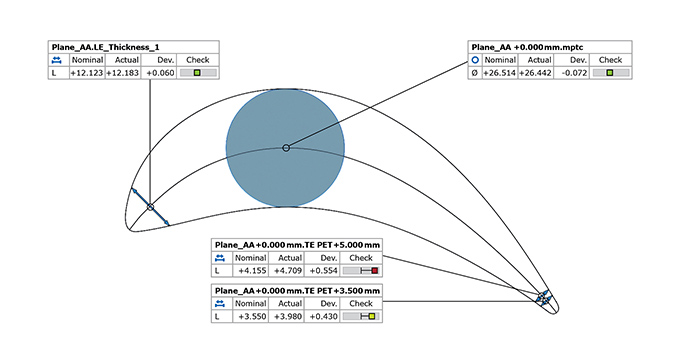

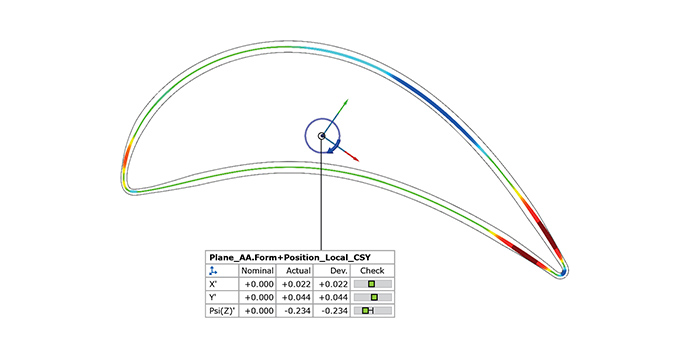

- สามารถตรวจสอบ Airfoil ได้อย่างมีประสิทธิภาพ

High stability

- มีระบบอัตโนมัติ ช่วยให้สามารถสแกนแบบความเร็วสูงได้

High-speed scanning

- ใช้เวลาในการสแกนเพียง 0.2 วินาที

GOM Data Quality

- มีซอฟต์แวร์ควบคุมการสแกนของเครื่อง 3D Scanner ให้ได้ข้อมูลที่แม่นยำ

Airfoil Inspection Features

ซอฟต์แวร์ GOM มีชุดฟังก์ชันการตรวจสอบ Airfoil โดยเฉพาะตามหลักการของ UDIP (User-Defined Inspection Principle) ช่วยให้ตรวจสอบส่วน Airfoil ได้อย่างรวดเร็ว ได้มาตรฐาน และมีประสิทธิภาพ

Edge Points and Edge Circles

Thicknesses

Form and Position Checks

ตรวจสอบเร็ว แม่นยำ คุณภาพสูงจาก GOM Atos 5 For Airfoil

Speed up your processes

ATOS 5 สำหรับ Airfoil เหมาะสำหรับวัดชิ้นงานที่ต้องการคุณภาพมาก และต้องการความรวดเร็วในการตรวจสอบ เช่น

- ข้อมูลของผลิตภัณฑ์ใหม่

- ชิ้นงานที่ต้องนำไป Maintenance

- ชิ้นงานที่ต้องส่งซ่อม

ซึ่งใช้เวลาเพียง 1 ในการสแกนTurbine blade และใช้เวลาประมาณ 20 นาที ในการสแกนใบพัดที่ประกอบเป็นชุดTurbine engine แล้ว รวมไปถึงใช้เวลาในการรับข้อมูลน้อยกว่า 1 ใน 5 วินาที

Achieve the highest data quality

ให้ข้อมูลที่มีความแม่นยำสูงสำหรับกระบวนการที่ครอบคลุมและการควบคุมคุณภาพ Turbine engine, Turbine blade และใบพัดแบบต่างๆ (NGV, OGV, IGV) คุณภาพของข้อมูลที่ได้จากเซ็นเซอร์ที่เป็นไปตามข้อกำหนดระดับสูงของอุตสาหกรรม สำหรับการวัดใบพัดกังหัน ที่ให้ความสำคัญกับค่าที่แม่นยำและความละเอียด

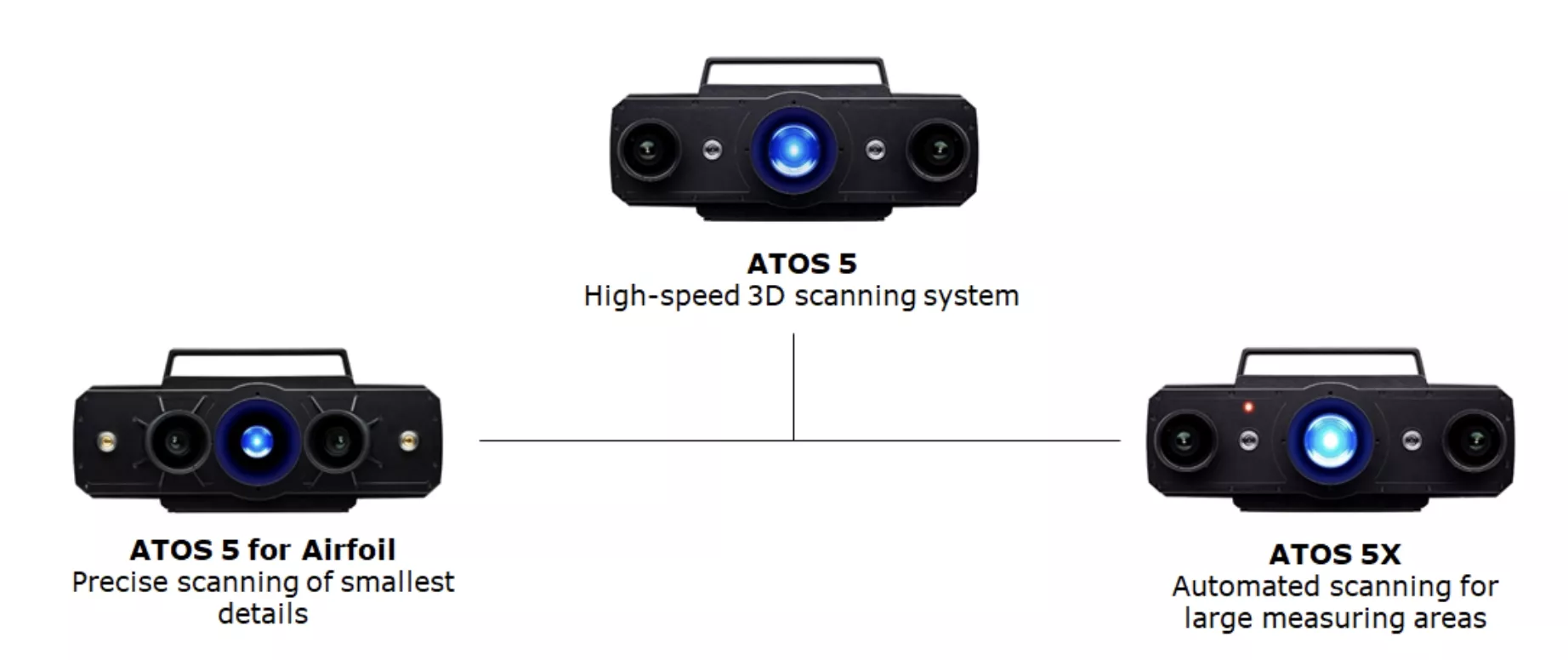

ข้อมูลทางเทคนิค (เครื่องสแกนเนอร์ ATOS 5)

| ATOS 5 for Airfoil | ATOS 5 | ATOS 5X | |

| Light source | LED | LED | Laser |

| Laser class | - | - | 2/3B * |

| Points per scan | 12 million | 12 or 8 million | 12 million |

| Weight | approx. 14 kg | approx. 14 kg | approx. 14 kg |

| Dimensions | approx. 550 mm x 320 mm x 200 mm | ||

| Housing | dustproof, splashproof | ||

| Cable length | fiber optic cable up to 30 m | ||

| Operating system | Windows 10 | ||

| Measuring volumes | 100,170,270,400 | 170,320,500,700, 1000 | 320,500,700,1000 |

| Measuring area [mm²] | 100 × 70 – 400 × 300 | 170 × 140 – 1000 × 800 | 320×250 – 1000× 800 |

| Point distance[mm] | 0.03 – 0.1 | 0.05 – 0.25 | 0.08 – 0.25 |

| Camera angle | 27.5° | 27.5° | 27.5° |

| Working distance [mm] | 530 | 880 | 880 |

* อ้างอิงตามมาตรฐาน IEC 60825-1: In 2014, classified as a Class 2 laser in automated use and as a Class 3B laser in manual use (safety distance without safety goggles > 700 mm).