JAKA Cobots

JAKA หุ่นยนต์แขนกลร่วมปฏิบัติงาน (COBOT 6 axis) มี Cobot หลายประเภทให้คุณเลือกใช้งาน สามารถยกชิ้นงานได้ตั้งแต่ 1 ถึง 18 กิโลกรัมและมีระยะการยืดถึง 1,327 มิลลิเมตร

JAKA Cobots

JAKA Collaborative Robots (JAKA Cobots) : มี Cobot หลายประเภทให้คุณเลือกใช้งาน สามารถยกชิ้นงานได้ตั้งแต่ 1 ถึง 18 กิโลกรัม และมีระยะการยืดถึง 1,327 มิลลิเมตร

แนะนำผลิตภัณฑ์ใหม่ “Jaka Pro”

Jaka Pro 5

น้ำหนักหุ่นยนต์ 23 กก.

น้ำหนักบรรทุก 5 กก.

ระยะยืด 954 มม.

IP68

Jaka Pro 12

น้ำหนักหุ่นยนต์ 41 กก.

น้ำหนักบรรทุก 12 กก.

ระยะยืด 1,327 มม.

IP68

Jaka Pro 16

น้ำหนักหุ่นยนต์ 73.9 กก.

น้ำหนักบรรทุก 16 กก.

ระยะยืด 1,713 มม.

IP68

คุณสมบัติเด่นของ Jaka Pro

- ปกป้องได้อย่างสมบูรณ์แบบ

- กันน้ำ และ กันฝุ่นละออง

- ปลอดภัย ใช้งานง่าย

เหมาะกับงาน

- ขนถ่ายวัสดุ เครื่องมือกล

- การตรวจสอบภายนอกอาคาร

- การดูแลอุปกรณ์

- การหยิบสินค้าทางการเกษตร

Jaka Zu 3

น้ำหนักหุ่นยนต์ 12 กก.

น้ำหนักบรรทุก 3 กก.

ระยะยืด 626 มม.

– ยืดหยุ่นและเบา

– ใช้พื้นที่ขนาดเล็ก

– ประหยัดงบประมาณ คุ้มค่าในการลงทุน

Jaka Zu 5

น้ำหนักหุ่นยนต์ 23 กก.

น้ำหนักบรรทุก 5 กก.

ระยะยืด 954 มม.

– ขนาดกระทัดรัด

– มีความยืดหยุ่นสูง

– สามารถปรับและเคลื่อนย้ายงานได้ดี

– ประหยัดงบประมาณ คุ้มค่าในการลงทุน

Jaka Zu 7

น้ำหนักหุ่นยนต์ 22 กก.

น้ำหนักบรรทุก 7 กก.

ระยะยืด 819 มม.

– รับน้ำหนักได้มาก (สัดส่วน 1:3 เมื่อเทียบกับน้ำหนักเครื่อง)

– มีความชาญฉลาด บังคับง่าย

– ประหยัดงบประมาณ คุ้มค่าในการลงทุน

Jaka Zu 12

น้ำหนักหุ่นยนต์ 41 กก.

น้ำหนักบรรทุก 12 กก.

ระยะยืด 1,327 มม.

– บรรทุกได้เยอะ

– ระยะยืดกว้าง

– มีความแข็งแรงสูง

– ประหยัดงบประมาณ คุ้มค่าในการลงทุน

Jaka Zu 18

น้ำหนักหุ่นยนต์ 35 กก.

น้ำหนักบรรทุก 18 กก.

ระยะยืด 1,073 มม.

– บรรทุกได้เยอะ

– มีความปลอดภัยสูง

– ประหยัดงบประมาณ คุ้มค่าในการลงทุน

Jaka Mini Cobots

น้ำหนักหุ่นยนต์ 8.7 กก.

น้ำหนักบรรทุก 1 กก.

ระยะยืด 576 มม.

– ขนาดเล็ก เคลื่อนย้ายสะดวก

– มีความแข็งแรงสูง

– ประหยัดงบประมาณ คุ้มค่าในการลงทุน

Overview : JAKA Cobots

ข้อดีของ JAKA Cobots :

ที่ผ่านมา JAKA หุ่นยนต์แขนกลประสบความสำเร็จเป็นอย่างสูงในการนำโคบอทไปใช้เพื่อการผลิตในภาคอุตสาหกรรม Jaka มีการพัฒนานวัตกรรมต่างๆ อย่างต่อเนื่อง เพื่อเป็น ความเป็นหนึ่ง JAKA Cobot จึงเป็นระบบอัตโนมัติ ที่ช่วยผลักดันอนาคตแห่งอุตสาหกรรมการผลิต

โซลูชั่นที่ JAKA Cobot สามารถช่วยคุณได้

- งานขันน็อต ขันสกรู

- งานขัด

- งานหยอดกาว

- หยิบจับและป้อนชิ้นงาน

- งานบรรจุ

- งานพ่นสี

- งานเชื่อม

- วางชิ้นงานบนพาเลท

- งานที่ต้องการความยืดหยุ่น

- งานที่มีกระบวนการซ้ำ ๆ

- งานที่ต้องการคุณภาพ

โคบอท JAKA ที่สุดของสมรรถนะการทำงานร่วมกับคน

เชื่อมต่อไร้สาย : ไม่ต้องใช้อุปกรณ์การสอนแบบเดิมๆ

สื่อสารได้อย่างปลอดภัย : มีเซ็นเซอร์ตรวจจับแรงบิดภายในข้อต่อ

โปรแกรมง่าย : ไม่ต้องมีประสบการ์ณก็สามารถใช้งานได้

ระบบปฏิบัติการแบบเปิด : ใช้งานกับระบบ ROS ได้

ปรับง่ายแขน : ง่ายต่อการขนส่ง

ไม่ต้องสอนการใช้งาน : – ใช้งานง่าย ไม่ยุ่งยากในการโปรแกรมการใช้งาน – ใช้ได้ทุกแพลตฟอร์ม

น้ำหนักเบา : น้ำหนักเบากว่าหุ่นยนต์ทั่วไป

ยกของได้เยอะ : สามารถรับน้ำหนักได้เยอะ

ถอดประกอบง่าย : ข้อต่อแต่ละข้อสามารถถอดประกอบได้อย่างรวดเร็ว

สามารถเคลื่อนย้ายไปยังจุดต่างได้ง่าย : ชิ้นส่วนทั้งหมดของหุ่นยนต์สามารถพับเก็บและพกพาได้

VDO : JAKA Automotive Industry

VDO : JAKA Food & Beverage Industry

กลุ่มอุตสาหกรรมใดที่ในอนาคต จำเป็นต้องใช้หุ่นยนต์ในกระบวนการผลิต

อิเล็กทรอนิกส์

การผลิต

ยานยนต์

การศึกษา

บริการ

อุปกรณ์ทางการแพทย์

แม่พิมพ์พลาสติก

อาหาร

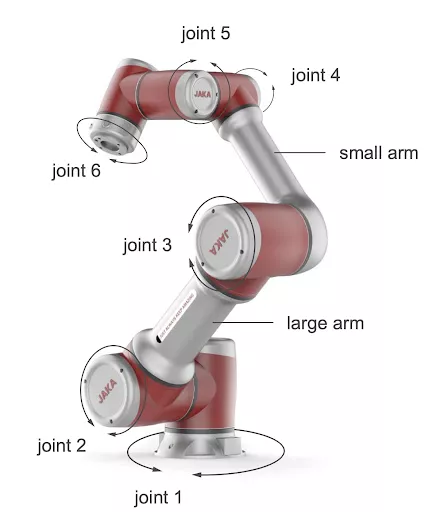

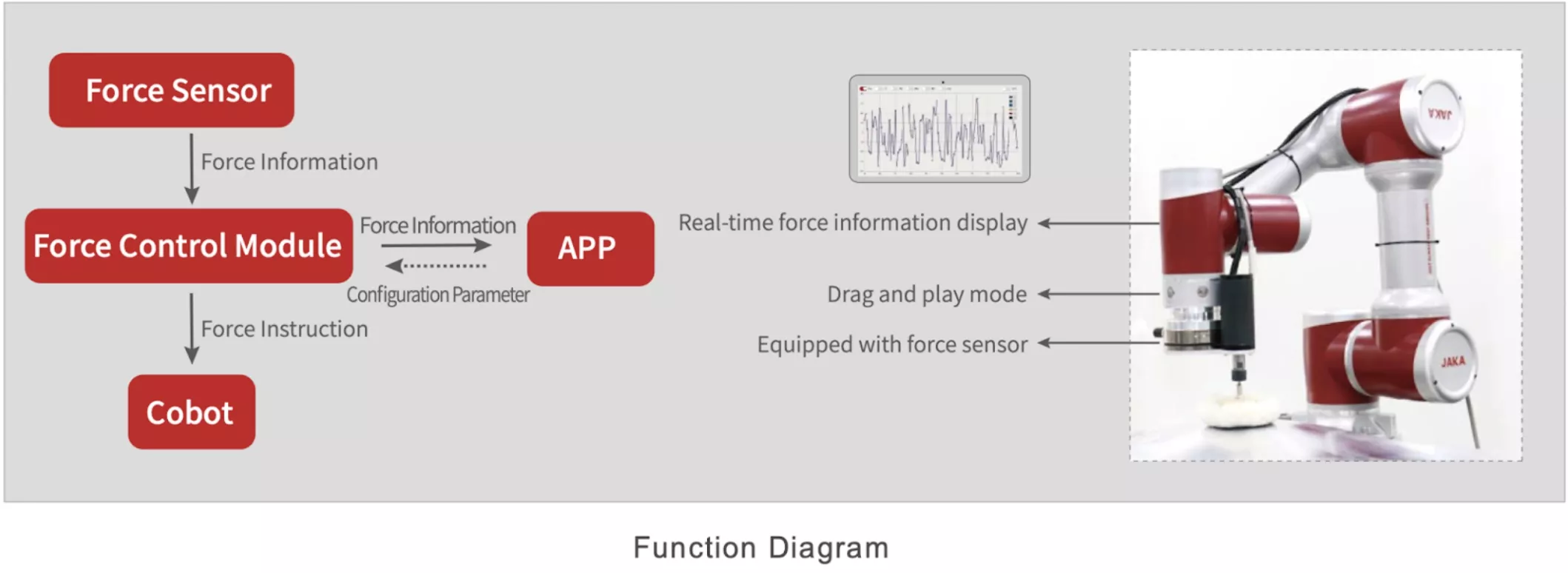

สเปกของแขนกล

| สเปกของแขนกล | |||||

| โมเดล | JAKA Zu 3 | JAKA Zu 5 | JAKA Zu 7 | JAKA Zu 12 | JAKA Zu 18 |

| รับน้ำหนักได้ | 3 Kg | 5 Kg | 7 Kg | 12 Kg | 18 Kg |

| น้ำหนักแขนกล (W cable) | 12 Kg | 23 Kg | 22 Kg | 41 Kg | 35 Kg |

| ระยะยืด | 626 mm | 954 mm | 819 mm | 1,327 mm | 1,073 mm |

| การทำซ้ำ | ±0.02 mm | ±0.02 mm | ±0.02 mm | ±0.03 mm | ±0.03 mm |

| แกน | 6 | 6 | 6 | 6 | 6 |

| ขนาดฐานหุ่นยนต์ | 129 mm | 158 mm | 158 mm | 188 mm | 188 mm |

| ขนาดบรรจุ (L×W×H) | 460×375×365mm | 460×375×365 mm | 620×415×445 mm | 875×580×520 mm | 770×510×505 mm |

| กำลังไฟ | 150 W | 350 W | 350 W | 500 W | 600 W |

| การตั้งโปรแกรม | Graphical programming, Free-drive | ||||

| การสอนการใช้ | MT(PAD/Mobile)APP | ||||

| การสื่อสารกับหุ่นยนต์ | In compliance with GB 11291.1-2011 | ||||

| ผ่านการรับรองจาก | CR, CE, 15066 | ||||

| อุณหภูมิ | 0-50 ํC | ||||

| มาตรฐาน IP | IP54 | ||||

| ความยาวของสายไฟ | 6 m | ||||

| พื้นที่การทำงาน & ความเร็วสูงสุด | ||||||

| Work scope | JAKA Zu 3 | JAKA Zu 5 | JAKA Zu 7 | JAKA Zu 12 | JAKA Zu 18 | |

| Joint 1 | ±360° | ±360° | ±360° | ±360° | ±360° | |

| Joint 2 | -85°,+265° | -85°,+265° | -85°,+265° | -85°,+265° | -85°,+265° | |

| Joint 3 | ±175° | ±175° | ±175° | ±175° | ±175° | |

| Joint 4 | -85°,+265° | -85°,+265° | -85°,+265° | -85°,+265° | -85°,+265° | |

| Joint 5 | ±360° | ±360° | ±360° | ±360° | ±360° | |

| Joint 6 | ±360° | ±360° | ±360° | ±360° | ±360° | |

| Max speed | JAKA Zu 3 | JAKA Zu 5 | JAKA Zu 7 | JAKA Zu 12 | JAKA Zu 18 | |

| Joint 1 | 180°/s | 180°/s | 180°/s | 120°/s | 120°/s | |

| Joint 2 | 180°/s | 180°/s | 180°/s | 120°/s | 120°/s | |

| Joint 3 | 180°/s | 180°/s | 180°/s | 180°/s | 180°/s | |

| Joint 4 | 220°/s | 180°/s | 180°/s | 180°/s° | 180°/s | |

| Joint 5 | 220°/s | 180°/s | 180°/s | 180°/s | 180°/s | |

| Joint 6 | 220°/s | 180°/s | 180°/s | 180°/s | 180°/s | |

| Max speed | 1.5 m/s | 3 m/s | 2.5 m/s | 3 m/s | 3.5 m/s | |

| ตู้คอนโทรล | |

| IP Specification | IP44 |

| Tool I/O | 16 Digital input , 16 Digital output 2 Analog input or output |

| Tool I/O Power | 24V |

| Communication | TCP/IP, Modbus TCP, Modbus RTU |

| Power | 100-240VAC, 50-60Hz |

| Size | 410×307×235 mm (WxHxD) |

| Weight | (Zu 3, Zu 5, Zu 7) : 12 Kg (Zu 12, Zu 18) : 16 Kg |

| Material | Stainless Steel |

| สเปกของแขนกล | |||||

| โมเดล | JAKA Zu 3 | JAKA Zu 5 | JAKA Zu 7 | JAKA Zu 12 | JAKA Zu 18 |

| รับน้ำหนักได้ | 3 Kg | 5 Kg | 7 Kg | 12 Kg | 18 Kg |

| น้ำหนักแขนกล (W cable) | 12 Kg | 23 Kg | 22 Kg | 41 Kg | 35 Kg |

| ระยะยืด | 626 mm | 954 mm | 819 mm | 1,327 mm | 1,073 mm |

| การทำซ้ำ | ±0.02 mm | ±0.02 mm | ±0.02 mm | ±0.03 mm | ±0.03 mm |

| แกน | 6 | 6 | 6 | 6 | 6 |

| ขนาดฐานหุ่นยนต์ | 129 mm | 158 mm | 158 mm | 188 mm | 188 mm |

| ขนาดบรรจุ (L×W×H) | 460×375×365mm | 460×375×365 mm | 620×415×445 mm | 875×580×520 mm | 770×510×505 mm |

| กำลังไฟ | 150 W | 350 W | 350 W | 500 W | 600 W |

| การตั้งโปรแกรม | Graphical programming, Free-drive | ||||

| การสอนการใช้ | MT(PAD/Mobile)APP | ||||

| การสื่อสารกับหุ่นยนต์ | In compliance with GB 11291.1-2011 | ||||

| ผ่านการรับรองจาก | CR, CE, 15066 | ||||

| กำลังไฟ | 150 W | 350 W | 350 W | 500 W | 600 W |

| อุณหภูมิ | 0-50 ํC | ||||

| มาตรฐาน IP | IP54 | ||||

| ความยาวของสายไฟ | 6 m | ||||

| พื้นที่การทำงาน & ความเร็วสูงสุด | ||||||

| Work scope | JAKA Zu 3 | JAKA Zu 5 | JAKA Zu 7 | JAKA Zu 12 | JAKA Zu 18 | |

| Joint 1 | ±360° | ±360° | ±360° | ±360° | ±360° | |

| Joint 2 | -85°,+265° | -85°,+265° | -85°,+265° | -85°,+265° | -85°,+265° | |

| Joint 3 | ±175° | ±175° | ±175° | ±175° | ±175° | |

| Joint 4 | -85°,+265° | -85°,+265° | -85°,+265° | -85°,+265° | -85°,+265° | |

| Joint 5 | ±360° | ±360° | ±360° | ±360° | ±360° | |

| Joint 6 | ±360° | ±360° | ±360° | ±360° | ±360° | |

| Max speed | JAKA Zu 3 | JAKA Zu 5 | JAKA Zu 7 | JAKA Zu 12 | JAKA Zu 18 | |

| Joint 1 | 180°/s | 180°/s | 180°/s | 120°/s | 120°/s | |

| Joint 2 | 180°/s | 180°/s | 180°/s | 120°/s | 120°/s | |

| Joint 3 | 180°/s | 180°/s | 180°/s | 180°/s | 180°/s | |

| Joint 4 | 220°/s | 180°/s | 180°/s | 180°/s° | 180°/s | |

| Joint 5 | 220°/s | 180°/s | 180°/s | 180°/s | 180°/s | |

| Joint 6 | 220°/s | 180°/s | 180°/s | 180°/s | 180°/s | |

| Max speed | 1.5 m/s | 3 m/s | 2.5 m/s | 3 m/s | 3.5 m/s | |

| ตู้คอนโทรล | |

| IP Specification | IP44 |

| Tool I/O | 16 Digital input , 16 Digital output 2 Analog input or output |

| Tool I/O Power | 24V |

| Communication | TCP/IP, Modbus TCP, Modbus RTU |

| Power | 100-240VAC, 50-60Hz |

| Size | 410×307×235 mm (WxHxD) |

| Weight | (Zu 3, Zu 5, Zu 7) : 12 Kg (Zu 12, Zu 18) : 16 Kg |

| Material | Stainless Steel |

รายละเอียดสินค้า

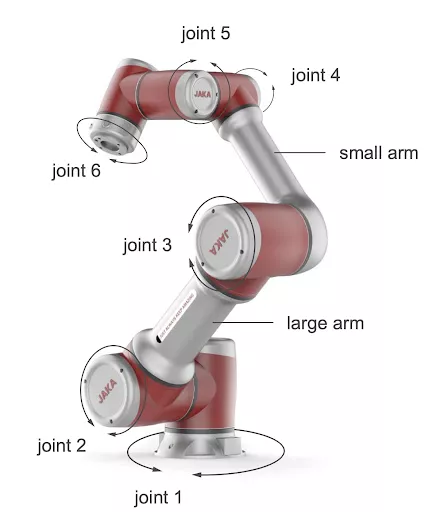

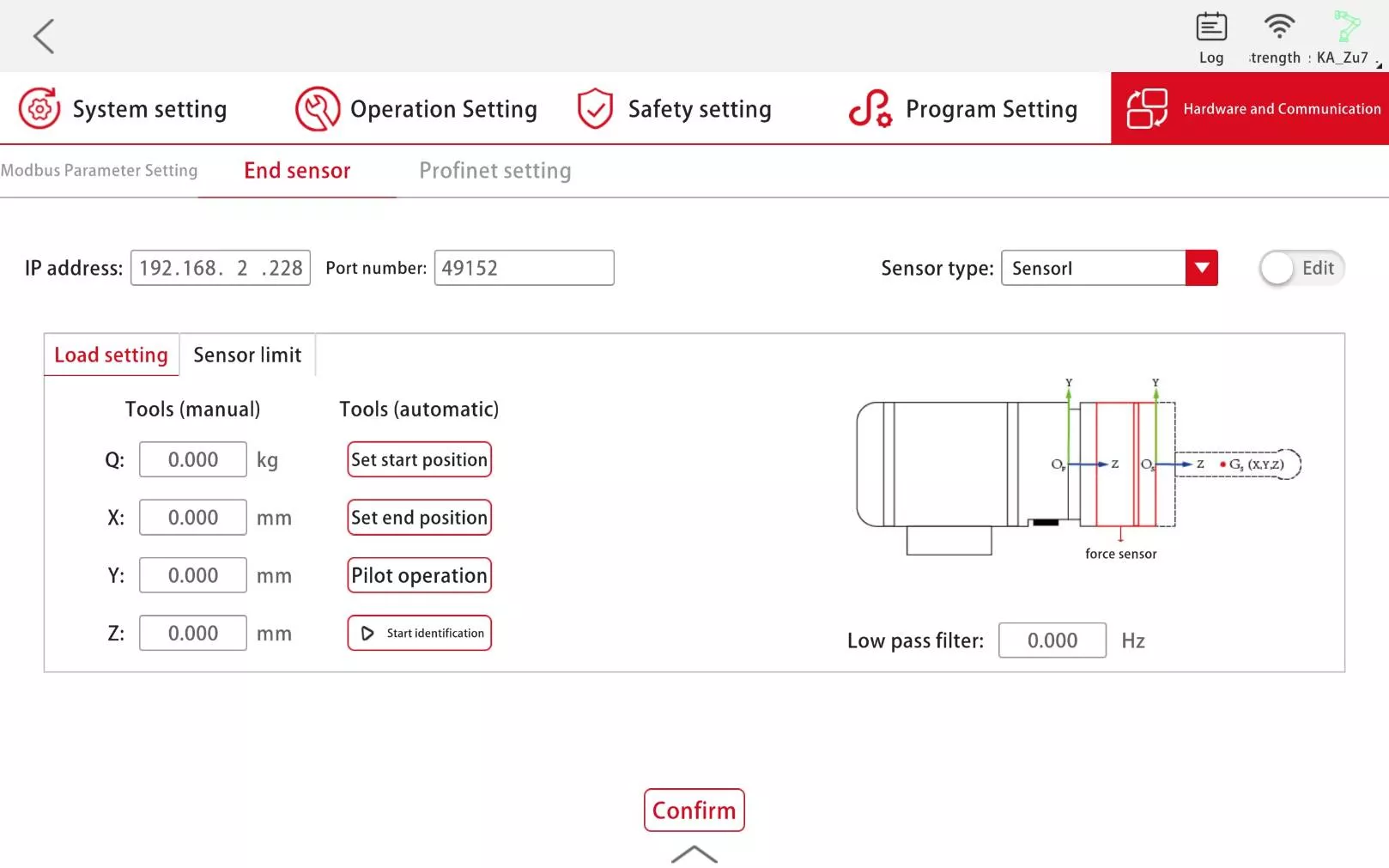

JAKA Zu S-series cobots ติดตั้งชุดควบคุมแรง (Force sensor) สามารถตั้งค่า,ควบคุมแรง เพื่อความปลอดภัยได้ สามารถระบุน้ำหนักที่หุ่นยนต์ถือได้อัตโนมัติ สามารถแสดงผลของแรงได้ตามเวลาจริง (real time) สะดวกต่อการควบคุม ซึ่งสามารถปรับค่าแรง และความเร็ว จากแอป จาก้าได้เลย

พารามิเตอร์พื้นฐาน :

- ชนิดอุปกรณ์ : Force sensor

- การเชื่อมต่อ : TCP/UDP

คุณสมบัติ :

- แสดงค่าของแรง ได้ตามเวลาจริง (real time)

- ตั้งค่าของแรงกระทำ , ควบคุมแรงได้บนแอป จาก้า

- สามารถควบคุมแรงที่ถูกกระทำ และควบคุมแรงที่ส่งออก (Force control)

- ตรวจจับการชนได้ครอบคลุมตลอดทั้งแขนของหุ่นยนต์

สเปกของแขนกล : JAKA Pro

| สเปกของแขนกล : JAKA Pro | |||

| โมเดล | JAKA Pro 5 | JAKA Pro 12 | JAKA Pro 16 |

| รับน้ำหนักได้ | 5 Kg | 12 Kg | 16 Kg |

| น้ำหนักแขนกล (W cable) | 23 Kg | 41 Kg | 73.9 Kg |

| ระยะยืด | 954 mm | 1,327 mm | 1,713 mm |

| การทำซ้ำ | ±0.02 mm | ±0.02 mm | ±0.02 mm |

| แกน | 6 | 6 | 6 |

| ขนาดฐานแขนกล | 158 mm | 188 mm | 246 mm |

| ขนาดบรรจุ (L×W×H) | 460×375×365mm | 460×375×365 mm | 620×415×445 mm |

| กำลังไฟ | 350 W | 500 W | 750 W |

| การตั้งโปรแกรม | Graphical programming, Free-drive | ||

| การสอนการใช้ | MT(PAD/Mobile)APP | ||

| การสื่อสารกับหุ่นยนต์ | In compliance with GB 11291.1-2011 | ||

| การติดตั้ง | Installation at any angle | ||

| อุณหภูมิ | 10-50 ํC | ||

| มาตรฐาน IP | IP68 | ||

| ความยาวของสายไฟ | 6M | ||

| พื้นที่การทำงาน & ความเร็วสูงสุด | ||||

| Work scope | JAKA Pro 5 | JAKA Pro 12 | JAKA Pro 16 | |

| Joint 1 | ±360° | ±360° | ±360° | |

| Joint 2 | -50°,+230° | -50°,+230° | -50°,+230° | |

| Joint 3 | ±155° | ±155° | ±155° | |

| Joint 4 | -85°,+265° | -85°,+265° | -85°,+265° | |

| Joint 5 | ±270° | ±270° | ±270° | |

| Joint 6 | ±270° | ±270° | ±270° | |

| Max speed | JAKA Pro 5 | JAKA Pro 12 | JAKA Pro 16 | |

| Joint 1 | 180°/s | 120°/s | 120°/s | |

| Joint 2 | 180°/s | 120°/s | 120°/s | |

| Joint 3 | 180°/s | 120°/s | 120°/s | |

| Joint 4 | 180°/s | 180°/s | 180°/s | |

| Joint 5 | 180°/s | 180°/s | 180°/s | |

| Joint 6 | 180°/s | 180°/s | 180°/s | |

| Max speed | 3 m/s | 3 m/s | 3.5 m/s | |

| สเปกของแขนกล : JAKA Pro | |||

| โมเดล | JAKA Pro 5 | JAKA Pro 12 | JAKA Pro 16 |

| รับน้ำหนักได้ | 5 Kg | 12 Kg | 16 Kg |

| น้ำหนักแขนกล (W cable) | 23 Kg | 41 Kg | 73.9 Kg |

| ระยะยืด | 954 mm | 1,327 mm | 1,713 mm |

| การทำซ้ำ | ±0.02 mm | ±0.02 mm | ±0.02 mm |

| แกน | 6 | 6 | 6 |

| ขนาดฐานแขนกล | 158 mm | 188 mm | 246 mm |

| ขนาดบรรจุ (L×W×H) | 460×375×365mm | 460×375×365 mm | 620×415×445 mm |

| กำลังไฟ | 350 W | 500 W | 750 W |

| การตั้งโปรแกรม | Graphical programming, Free-drive | ||

| การสอนการใช้ | MT(PAD/Mobile)APP | ||

| การสื่อสารกับหุ่นยนต์ | In compliance with GB 11291.1-2011 | ||

| การติดตั้ง | Installation at any angle | ||

| อุณหภูมิ | 10-50 ํC | ||

| มาตรฐาน IP | IP68 | ||

| ความยาวของสายไฟ | 6M | ||

| พื้นที่การทำงาน & ความเร็วสูงสุด | ||||

| Work scope | JAKA Pro 5 | JAKA Pro 12 | JAKA Pro 16 | |

| Joint 1 | ±360° | ±360° | ±360° | |

| Joint 2 | -50°,+230° | -50°,+230° | -50°,+230° | |

| Joint 3 | ±155° | ±155° | ±155° | |

| Joint 4 | -85°,+265° | -85°,+265° | -85°,+265° | |

| Joint 5 | ±270° | ±270° | ±270° | |

| Joint 6 | ±270° | ±270° | ±270° | |

| Max speed | JAKA Pro 5 | JAKA Pro 12 | JAKA Pro 16 | |

| Joint 1 | 180°/s | 120°/s | 120°/s | |

| Joint 2 | 180°/s | 120°/s | 120°/s | |

| Joint 3 | 180°/s | 120°/s | 120°/s | |

| Joint 4 | 180°/s | 180°/s | 180°/s | |

| Joint 5 | 180°/s | 180°/s | 180°/s | |

| Joint 6 | 180°/s | 180°/s | 180°/s | |

| Max speed | 3 m/s | 3 m/s | 3.5 m/s | |