Bentley AutoPIPE Connect

The Most Productive Tool for Pipe Stress Analysis

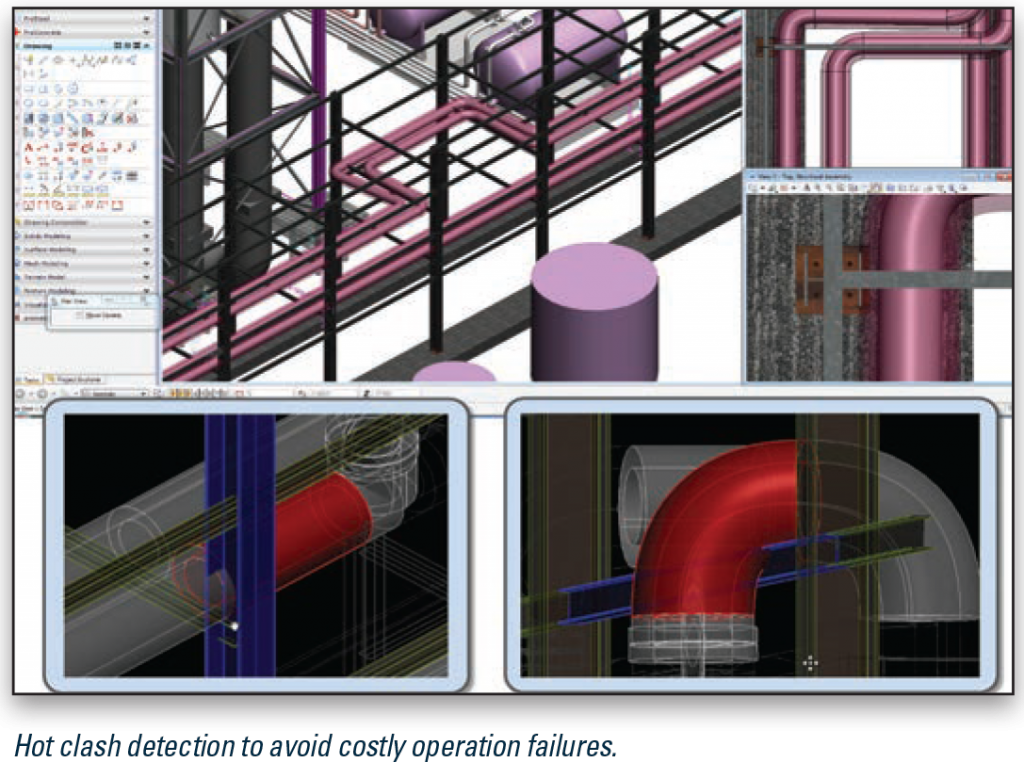

Bentley AutoPIPE V8i is the most productive design and analysis program for calculating piping code stresses, loads, and deflections under static and dynamic load conditions, even to the highest nuclear standards. Costly plant shutdowns caused by pipes moving as they heat up can be avoided with 3D ‘hot’ clash detection. This functionality can also be used to avoid piping failures during extreme loading conditions (like earthquakes). AutoPIPE also includes special features for advanced buried pipeline analysis, wave loading, fluid transients, FRP/GRP or plastic pipe, as well as time saving integrations with STAAD.Pro and all major plant design systems.

Unique, Object-based Graphical User Interface

The OpenGL CAD graphical user interface found in Bentley AutoPIPE V8i enables users to easily create and modify the pipe stress model. Users can simply point and click on the graphical model to insert, modify, or delete pipe supports, loads, or components. After each operation, the model display is automatically updated for instant visual feedback. Using AutoPIPE V8i graphical select options, users can insert, delete, or modify components, supports, pipe properties, temperatures/pressures, or other parameters across an entire range of points with one command. Graphical selection of ranges is also used to cut, copy, and paste operations. Users can check, sort, or make changes to the input data quickly using interactive grid spreadsheets like Excel. AutoPIPE V8i features up to 99 undo or redo steps to correct mistakes, perform ‘What-if’ analysis, or to iterate quickly through design scenarios.

Advanced Analysis Features for Varied Piping Environments

AutoPIPE V8i provides unique capabilities for process, power, oil and gas, nuclear, underground, offshore floating, production, storage, and offloading (FPSO) platform and subsea pipeline areas with 25 international piping codes. Advanced AutoPIPE V8i capabilities include built-in wave loading, buried pipeline analysis, jacketed piping, dynamic loadings, orthotropic fiberglass reinforced plastic (FRP/GRP), and HDPE plastic piping analysis. It also includes thermal stratification or bowing, thermal transient, pipe/structure interaction, fluid transient with closure time and relief

valve utilities, advanced load sequencing, non-linear support gaps and friction and jacketed piping. Local stress calculation to WRC 107, WRC 297, PD 5500, KHK, API 650 is available using AutoPIPE Nozzle.

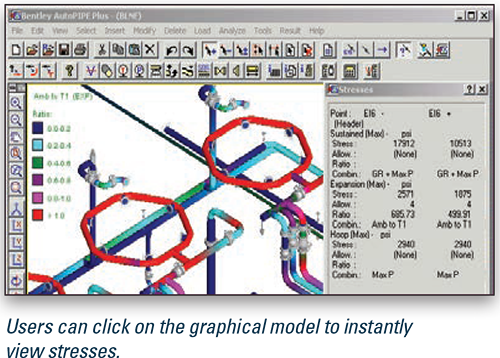

Graphical Review of Analysis Results

Once a system is analyzed, users can click on the graphical model and instantly view stresses, deflections, forces, and moments. Color-coded results and pop-up windows enable users to quickly identify and investigate critical areas without having to review a voluminous amount of batch output data. Up to 1000 load combinations can be viewed with the powerful on-screen results grid, which provides interactive filtering, sorting, and printing of maximum result values.

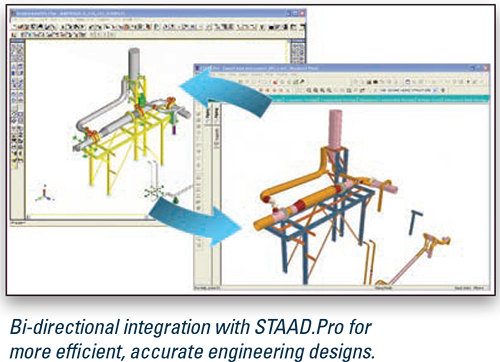

Interface with ProjectWise, CAE, STAAD.Pro and Plant Design CAD Systems

The only solution on the market today for a truly integrated design between piping and structural analysis, AutoPIPE V8i can automatically transfer pipe support loads as well as import complete structures to and from STAAD.Pro V8i, saving weeks of design time and providing safer, more-realistic engineered designs. Import 3D plant design CAD models from AutoPLANT® V8i, PlantSpace® V8i, OpenPlant® V8i, Intergraph PDS®, SmartPlant®, CADWORX®, SolidWorks®, Inventor®, Plant 3D, CATIA®, and Aveva PDMS®, into AutoPIPE® V8i to save hundreds of man hours and ensure accurate pipe stress models.

AutoPIPE V8i provides users with full read/write interoperability with Caesar II, and its models and data can be read by Bentley Navigator or MicroStation® alongside any CAD model to support early engineering decision making, perform 3D

‘hot’ clash detection, and reduce design iterations. AutoPIPE also generates fully dimensioned stress isometrics with custom data and comments highlighting the pipe stress engineer’s changes. In addition, AutoPIPE V8i is integrated with ProjectWise for global collaboration of engineering and CAD data files on major projects

Quality Assurance

AutoPIPE V8i rigorous quality assurance program has passed numerous nuclear and Nuclear Procurement Issues Committee (NUPIC) audits to 10CFR50 App. B, ISO9001, CSA N286.7-99, ASME NQA-1, and ANSI N45.2 standards, making Bentley AutoPIPE V8i one of the few pipe stress programs with a high-level of quality. AutoPIPE Nuclear V8i provides design of critical safety pipework to ASME Class 1, 2, or 3.

Bentley AutoPIPE V8i At-A-Glance

Modeling

• Single line, wire-frame and solid render drawing modes

• CAD style single, double, or quad view ports

• Vertical axis (Y or Z) can be switched on the fly

• On-screen distance calculator for accurate

coordinate checks

• Built-in valve actuator for more accurate valve modeling

• Segment management: reverse, split, join, and

re-order segments

• CAD line class and line numbers

• Connectivity checker to avoid model disconnects

• English, metric, SI, and user-defined units

• Extensive ANSI/ASME, DIN, EN, JIS, GD, GB, GOST, and

GRP/FRP standard piping component and material libraries

• Structural steel modeling using structural databases

for 17 countries

• Expansion joint modeling with tie rod assemblies

• Model import from AutoPLANT® V8i, PlantSpace® V8i,

OpenPlant® V8i, MicroStation®, Excel®, AutoCAD®,

Intergraph PDS®, SmartPlant®, Aveva PDMS®, CADWORX®,

SolidWorks®, Inventor®, Plant 3D, CATIA®, and PlantFLOW®

• PIPELINK bi-directional integration with STAAD.Pro V8i

• Automatic stress isometric generation in DXF, DWG

or DGN formats with engineers mark-ups

• Model geometry data export into AutoPLANT® V8i,

MicroStation® V8i, and AutoCAD®

• Automated ring main wizard

• Automatic ASCE soil calculator

Dynamic Analysis

• Time history dynamic analysis with ground motion

• Mode shapes, accelerations, and natural frequencies

• Harmonic load analysis

• Uniform & MSRS response spectrum and shock spectra

• Multiple spectrum enveloping

• NRC spectra and code case N411 (PVRC) damping

and spectra

• NUREG.CR-1677, CR-6414 and CR-6049 benchmarks

• Automatic mass discretization

• Missing mass and ZPA correction

Piping Codes

• ASME B31.1 (multiple years), B31.3, B31.4, and B31.8

• ASME Sec. 3, Class I, II, and III (multiple years from 1972)

• European Standard Metallic Industrial Piping EN13480

• B31.4, B31.8, B31.4 Offshore, B31.8 Offshore and

CSA_Z662 Offshore codes, DNV OS F101 offshore code

• Canadian CAN/CSA–Z662

• British Standard BS 806, BS 7159 (GRP piping code)

• FRP ISO 14692

• ASME N755 HDPE Code Case

• Russian SNIP 2.05.06-85 Oil and Gas

• Swedish Piping Code (SPC) Method 2

• Norwegian Det Norske Veritas (DNV) and TBK 5-6

• Dutch Stoomwezen D1101

• Japanese KHK, MITI class 3, JSME NC1-PPC and

General Fire Protection code

• French RCC-M and SNCT

Analysis

• Unlimited static analysis to examine different loading

scenarios including hot modulus for any combination of

100 thermal, 10 seismic, 10 wind, and 50 dynamic load cases.

• Automatic generation of wind profiles per ASCE and

UBC guidelines

• Wave loading and buoyancy for offshore applications

• Hydrotest analysis with locking spring hangers

• Fluid transient utilities for water and steam hammer

plus relief valve load analysis

• Automatic spring hanger sizing from 27 manufacturers

• State-of-the-art nonlinear support gap, friction, yielding,

and soil interaction with advanced features of seismic

wave propagation, overburden and settlement loads,

and stresses to ASCE, AWWA, and ASME

• Thermal stratification bowing analysis

• Thermal transient analysis (TTA), fatigue and high

energy/leakage design for ASME Class 1

• Seismic static and response spectra load generator

to IBC, Euro, ASCE, Indian, Spanish, Mexican, and

Chinese, standards

• Ec/Eh ratio applied to expansion stresses for

any piping code

• Integrated flange loading analysis per ASME VIII

Div 1 and 2, ASME III App XI, and ANSI B16.5

• Nozzle flexibility analysis per API 650 App. P,

ASME Class 1, WRC 297 and Biljaard methods

Input and Results

• Results saved to Microsoft Access MDB file for

post-processing

• Automatic or user-defined load combinations grid

• Automated batch processing

• Maximum intermediate stresses

• Reference point for manufacturer equipment

loading reports

• Rotating equipment calculations to API 610, NEMA and

API 617, and user-defined standards

• Results can be filtered and sorted by stress, deflection,

or load criteria