STRATASYS H350 – Unlock the experience of 3D Printing

STRATASYS H350 3D printer meet your production needs with SAF™ (Selective Absorption Fusion™), the latest technology from Stratasys

Additive Manufacturing on a New Level

Get Higher-Volume Production With SAF 3D Printing Technology

Stratasys H350 3D printer unlocks the power of 3D printing, meeting production needs with SAF™ (Selective Absorption Fusion™), the latest technology from Stratasys.

Highlights of the Stratasys® H350™

- SAF™ helps you to control production and costs.

- Can be produced in large quantities within short time.

- Quality manufactured parts can actually be used.

H350 : New SAF Technology Machine

H350 Applications

Quality finished, end-use products

Suitable for workpieces with a smooth surface and high quality, such as phones, headphones, eyeglasses, cases, and electronic equipment storage boxes

Molds, and robust load bearing parts

Tools, machine parts, fixtures, adapters, and accessories for production

Functionally enhanced parts

Parts that are specific operating modes include hinges, gears, clips, flaps, and lids

How does the H350 help?

- Production Control: Quality of models manufacturing precision.

- Control the working method: check the amount of material used, collect model data Easily adjust print settings, including a quality print head that is stable in operation.

- Controlling production costs: accurately assess the use of materials use fewer consumables. All variables that occur during printing can be controlled. The machine is durable and stable, thereby helping to lean production costs can increase business profit.

PEAK ACCURACY, TIME AFTER TIME

TAKE CONTROL OF YOUR WORKFLOW

CUT OUT HIDDEN PRINT COSTS

H350 Materials

Produce engineering-grade parts.

High Yield PA11 : Engineering-grade polymer

PA11 is a more substantial material and tougher than PA 12 and also impacts resistance and heat resistance. As for the surface of the printed workpiece, it will be smoother than the part printed with FDM and PA11 is also a type of environmentally friendly biomaterial.

H350 Specifications

| Technology : | SAF Technology |

| Material (Powder) : | Stratasys High Yield PA11 |

| Material (Fluid) : | Stratasys High Absorption Fluid HAF TM |

| Build Size (xyz) : | 315 x 208 x 293 mm (12.40 x 8.18 x 11.53 in) |

| System Size and Weight : | 1900 x 940 x 1730 mm (74.8 x 37.0 x 68.1 in) 825 kg (1819 lb) |

| Layer Thickness : | 100 μ (0.004 in) |

| Time to a full build : | 11.62 hrs. |

| BUILD MODES : | High Quality Speed (HQS) – 18.75µm |

| Operating Conditions : | – Temperature: 20-25˚ C – Humidity: [40-55]% RH – Extraction rate: 300 m3/h (294 CFM) |

| Power Requirements : | 400VAC, 3P+N, PE, 50-60 Hz, 16A |

| Certificates : | – Safety: EN ISO 12100:2010 – Electromagnetic: DIRECTIVE 2014/30/EU – Environmental: REACH, RoHS, WEEE, Modern Slavery Act, CoA, CoC (and from 2021, Conflict Minerals regulation), TSCA |

| Software : | – GrabCAD Print Server |

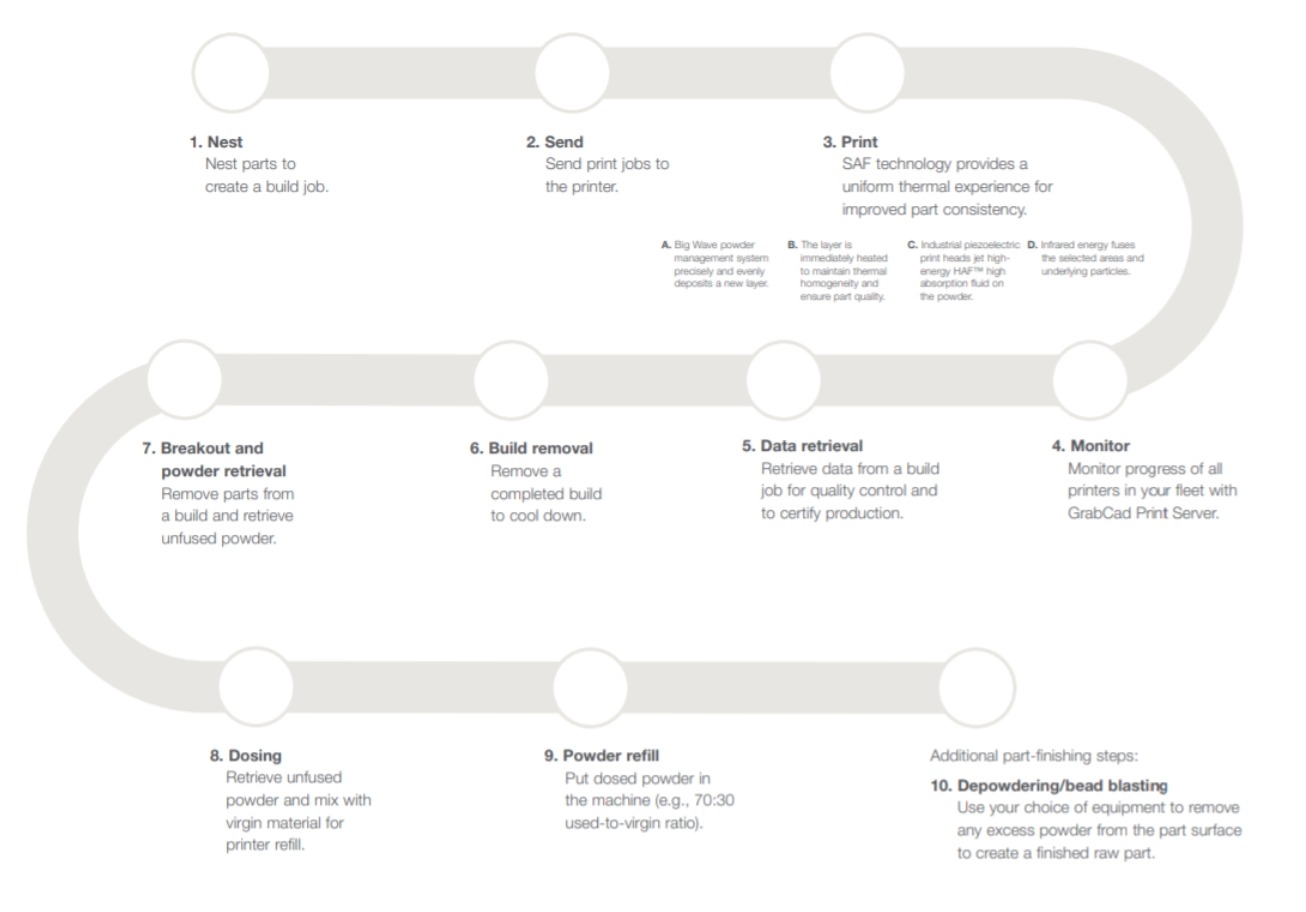

Q : What is SAF technology, and how does it work?

A : SAF Selective Absorption Fusion is the 3D printing technology behind the H Series manufacturing platform. SAF is a type of PBF 3D printing process based on ASTM standards. SAF technology uses infrared-sensitive HAF (High Absorbing Fluid) to Fusing the particles of polymer powder together. Use powder handling during production with Big Wave™. This proprietary technology includes dispersing the powder over the printing area using an industrial-grade piezoelectric print head spraying liquid in a designated area to create individual layers of the part. This is followed by exposure to infrared energy, which causes the HAF-containing region to melt and repeat each layer until complete.

Introducing the H Series™ Production Platform

Q : How is SAF technology different from PBF (powder bed fusion)?

A : The main difference with SAF is how the polymer powders are heat dissipated and fused. SAF technology provides a high level of component detail without using a single High Absorption Fluid. The unique technology ensures that enough power is available to cover the entire next layer even when printing large cross-sectional areas and reduces the life of the powder. This results in more excellent thermal stability, which produces better results in part repeatability and uniformity of material properties.

Q : How H350 works?

“The H350TM 3D printer provides us with a strong solution for volume production to manufacture cost-effectively and in short lead times.”

Philipp Goetz

Owner of Goetz Maschinenbau

Read more : STRATASYS