Stratasys® F123CR

Stratasys® F123CR Forget CNC programming. Forget multiple tool setups.Forget finding skilled.

Stratasys F123 CR. Composite 3D Printings

3D Pinter F123 CR Forget CNC programming. Forget multiple tool setups.Forget finding skilled

Stratasys® F123 CR

The F123CR (Composite Ready) Series consists of the F190™CR and the F370®CR, two composite printers that offer high-strength carbon fiber materials in a reliable, user-friendly industrial printer platform.

- 80% labor time savings

- 42% reduction in cost per part using Stratasys 3D

Applications in Manufacturing

- Manufacturing Tooling

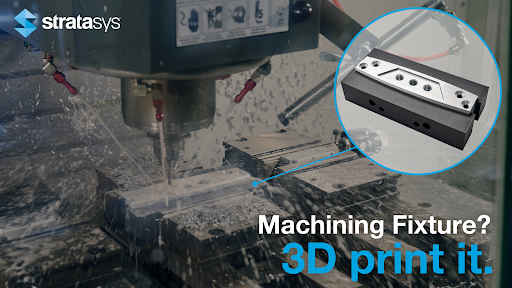

- Workholding Fixtures

- Functional Prototyping

- Low-volume production parts

Sample Applications

- Molding (Injection)

- Robotic end effectors

- Casting patterns

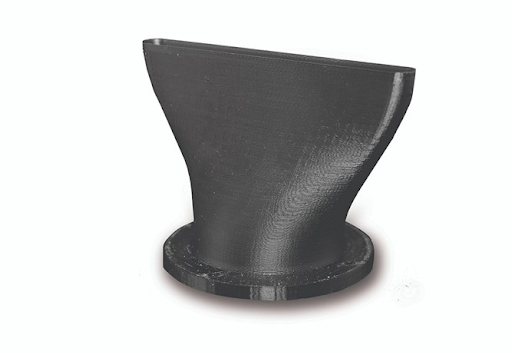

- Forming (metal, thermoforming, vacuum)

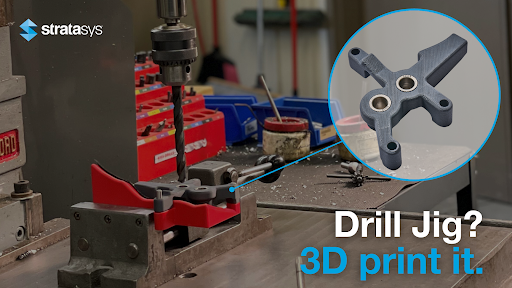

- Machining, jigs, clamps and drill guides

- Soft Jaws

3D Printer Materials :

Stratasys® F123 Composite Ready

ABS-CF10

ABS-CF10 combines the benefits of a carbon fiber filament with the desirable mechanical properties and ease of use of ABS 3D printing material.

ABS-M30

ABS-M30 is a strong, tough thermoplastic appropriate for many 3D printing applications.

ASA

ASA is similar to ABS but is UV resistant and produces a smoother printed surface.

FDM TPU 92AFDM TPU 92A

FDM TPU 92A is a thermoplastic polyurethane for flexible elastomer parts.

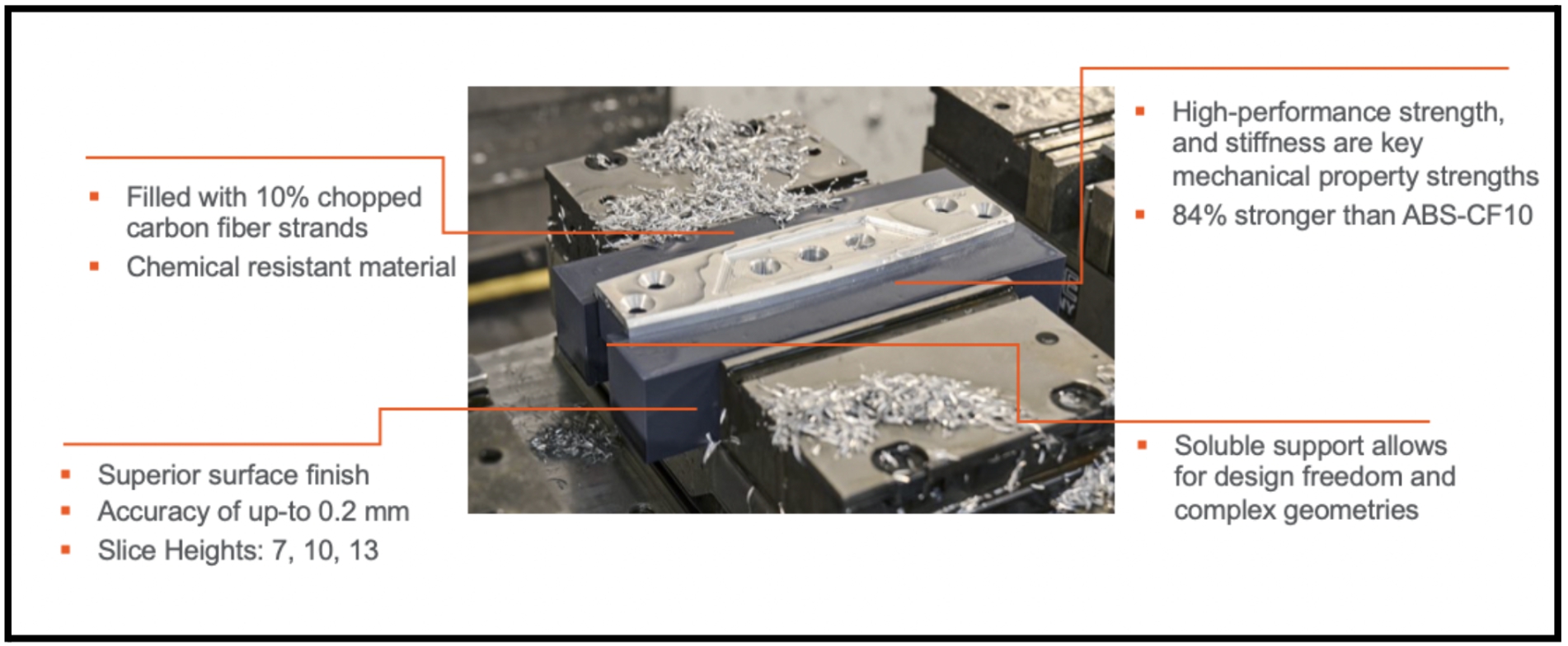

FDM Nylon-CF10 (Special Material)

FDM Nylon-CF10 is a nylon carbon fiber material offering increased strength and rigidity for demanding tooling and part applications

ABS-ESD7 (F370CR)

ABS-ESD7 has static dissipative qualities making it suitable for applications involving electronics.

PC- ABS (F370CR)

PC-ABS blends the desirable attributes of polycarbonate with ABS.

Diran 410MF07 (F370CR)

Diran 410MF07 is a durable, nylon-based thermoplastic with exceptional toughness, smoothness and resistance to hydrocarbon-based chemicals.

Key Features : Stratasys F123CR Series

- Fully Heated Build Chamber

- A built-in camera provides visual remote print monitoring

- GrabCAD Print™ and Insight™ software provide a simple workflow and in-depth print process control

- Automatic Material Change (Auto changeover capability on the Stratasys F370CR extends print times and printers are mounted on casters for easy mobility.)

- The Stratasys F123CR series gives the option of up to 8 different Fused Deposition Modeling materials

- Easy-to-remove soluble support material.

Stratasys F123 Comparison

| Model | F170 | F190 CR | F370 | F370 CR |

| Build Tray | 10 inches x 10 inches | 12 inches x 10 inches | 14 inches x 10 inches | 14 inches x 10 inches |

| Model Materials | 5 types consisting of

|

5 types consisting of

|

8 types consisting of

|

8 types consisting of

|

| Support Material | QSR | QSR | QSR |

|

| Material Delivery | 2 material spool bays, 1 for model, 1 for support located in a drawer on the front of the unit | 4 material spool bays, 2 for model, 2 for support located in a drawer on the front of the unit | ||

| Software |

|

|

||

| System Size | 1626 mm x 864 mm x 711 mm | |||

| Weight | 227 kg | |||

| Accuracy | Parts are produced within an accuracy of +/- .200 mm or +/- .002 mm/mm. whichever is greater | |||

| Power Requirements | 100-132V/15A or 200–240V/7A. 50/60 Hz | |||

| Compliance Certificates | CE (low-voltage and EMC directive), FCC, EAC, cTUVus, FCC, KC, RoHs, WEEE, Reach, RCM. | |||

F123 CR Material Thickness

| 3D Printer Materials | Layer Thickness | |||

| 0.330 MM | 0.254 MM | 0.178 MM | 0.127 MM | |

| ABS-M30 | 🔵 | 🔵 | 🔵 | 🔵 |

| ASA | 🔵 | 🔵 | 🔵 | 🔵 |

| PC-ABS | 🔵 | 🔵 | 🔵 | 🔵 |

| ABS-ESD7 | 🔵 | 🔵 | ||

| Diran 410MF07 | 🔵 | 🔵 | ||

| FDM TPU 92A | 🔵 | 🔵 | ||

| ABS-CF10 (1) | 🔵 | 🔵 | 🔵 | |

| FDM Nylon-CF10 (2) | 🔵 | 🔵 | 🔵 | |

- Hardened print head is recommended for extended head life but will also operate using standard F123 and ABS-CF10 print heads.

- Dedicated FDM Nylon-CF10 hardened print head required.

Stratasys F123 CR Sample Part

Stratasys F123 CR

Press Brake Tool

Stratasys F123CR

Press Brake Tool

Stratasys F123CR

Soft Jaw Application

Stratasys F123CR

Machining Fixture

FDM Nylon-CF10

F190CRd an F370CR