Shop System™

Shop System. Metal binder jetting designed for machine shops.

Overview

The Desktop Metal Shop System ™ is the world’s first metal binder jetting system designed specifically for machine shops.

- High-speed and single-pass print engine,

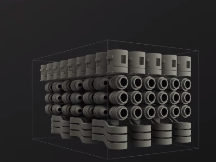

- Produce high-quality metal parts up to 10 times faster than laser powder bed fusion

- Up to 70 kg of metal parts per day.

With the Desktop Metal Shop System ™, shop owners can eliminate many of the constraints previously seen with traditional manufacturing methods like CNC machining and tap into new opportunities to reduce their costs and increase revenue.

Highlight

1. Unparalleled Productivity – Amplify your shop’s output. Effortlessly print end-use metal parts with the quality, surface finish and tolerances required to co-exist with machining.

Up to 10x faster than laser powder bed fusion

- producing up to 70kg of metal parts per day.

Print a build / shift

- 6-12 hour build time*

- Effortless productivity

- Save machinist hours with near-net-shape parts

Ultimate flexibility

- No tooling required

- No custom set-ups required per design

- Simultaneously produce multiple complex jobs

- Easily switch powders in a single shift

2. Best in class print quality – Print customer-ready, high-resolution parts with incredibly fine feature detail. Achieve surface finishes as low as 4µm Ra out of the furnace, and <0.1µm Ra with mass finishing. The Shop System produces fully dense, solid parts, no debind or infill required.

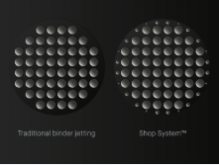

High-resolution printing

The Shop System features the highest resolution single-pass binder jetting system in the market.

- 1600 x 1600 native DPI

- Over 670 million drops/second

Adaptive print engine

Users don’t have to sacrifice feature detail or resolution for speed.

- Smallest droplet size (~1 pL)

- Automated drop multiplexing

- Surface finish as low as 4 μm Ra

5x print redundancy

- 5 independent channels of nozzles

- Over 70,000nozzles across 5 lines

- 25% higher redundancy than comparable systems

3. Easy to use and operate Designed with the modern machine shop in mind.

- Seamlessly fits into your workflow

- Superior part quality at a fraction of the cost

Affordable turnkey solution

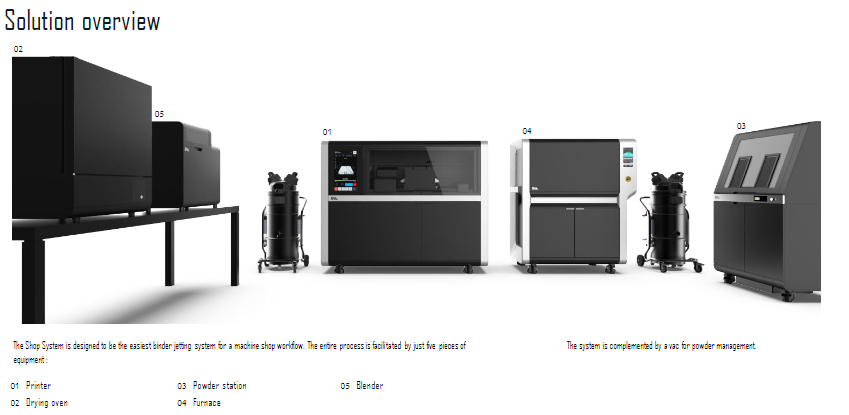

The Shop System contains all pieces of equipment your machine shop needs to begin binder jetting — from print through sintering. And with a range of build volume configurations (4L, 8L, 12L, and 16L), the Shop System is designed to scale to your shop’s throughput.

Simplified post-processing

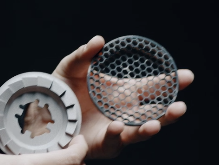

Parts on the Shop System print fully supported in their powder bed, and feature hand-removable sintering setters.

- No print supports required

- No EDM’ing support structures

- Hand-removable sintering supports

Optimized powders & parameters

- Turnkey, end-to-end solution

- Desktop Metal engineered powders and processing parameters,

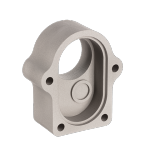

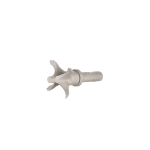

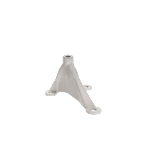

Application

The Desktop Metal Shop System™ applications span a variety of industries including manufacturing, tooling, automotive, consumer, electronics, and oil & gas.

Flexible manufacturing – The Shop System™ is designed to seamlessly integrate into your shop’s workflow to improve productivity across any range of manufacturing scenarios.

1. Mixed-Volume ProductionAffordable turnkey solution

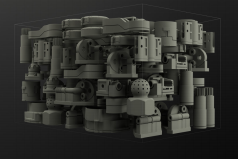

Produce various part geometries simultaneously without the need for multiple setups.

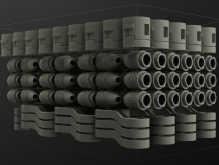

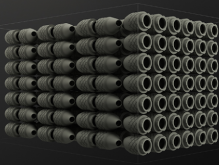

2. Batch Production

Cost effectively produces low volume batches of complex parts due to elimination of tooling.

3. Mid-Volume Production

Produce hundreds of near-net-shape parts every day with dramatically reduced labor costs and expanded geometric flexibility.

Materials

The system is compatible with powders from traditional powder metallurgy processes including stainless steels, tool steels, and super alloys. Get started quickly with a turnkey, end-to-end solution. Shop System features Desktop Metal™ engineered powders and processing parameters, optimized to deliver exceptional part quality, and ensure part-to-part repeatability.

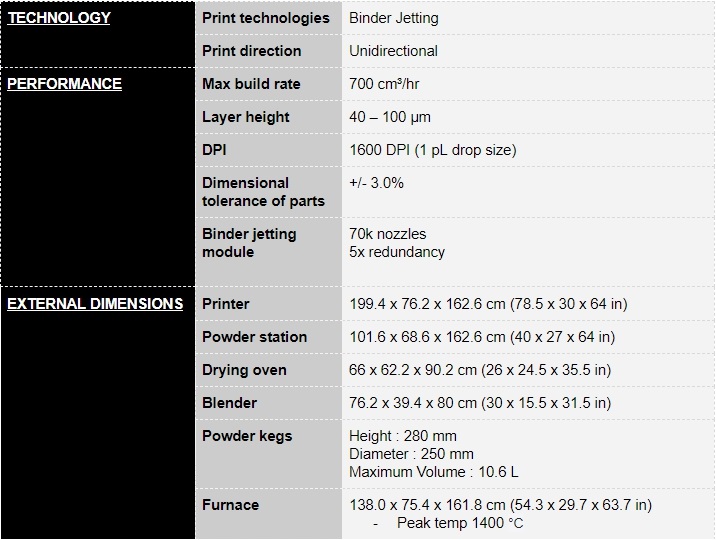

Specification

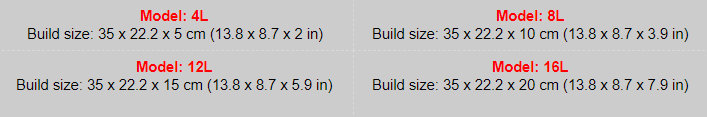

The Desktop Metal Shop System ™ comes in four models to enable you to tailor the solution for your needs.

Technology

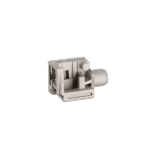

The Desktop Metal Shop System ™ is an end-to-end, single-pass binder jetting solution delivering high-resolution parts at a fraction of the time and cost. Metal parts are created with the following the process:

1. Perp

Secure, web-based software constructs build plans from your STL or CAD files to automatically generate support and control parameters based on part geometry and material.

2. Print

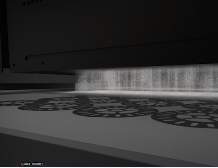

For each layer, the printer spreads metal powder across the build bed, and precisely jets a binding agent to bond loose powder and define part geometry. Layer by layer, metal powder and binder is deposited until the entire build volume is packed with bound parts and surrounding loose powder.

3. Depowder

Once an entire build is complete, the build box is removed and placed in a powder station for bulk and fine depowdering — with the help of a hand-held air pick. Loose powder is removed from the parts and recovered via a built-in powder recycling system with powder sieving.

4. Sinter

Depowdered parts are placed onto trays in a shop-safe, high-throughput furnace for batch sintering. With an external gas hookup and temperatures reaching 1400ºC, the Shop System furnace is able to deliver quality and reliable sintering in a shop-friendly format.