One Click Metal

HOLISTIC.

AFFORDBALE.

MADE WITH MIND.

Print – Unpack – Sieve – Repeat

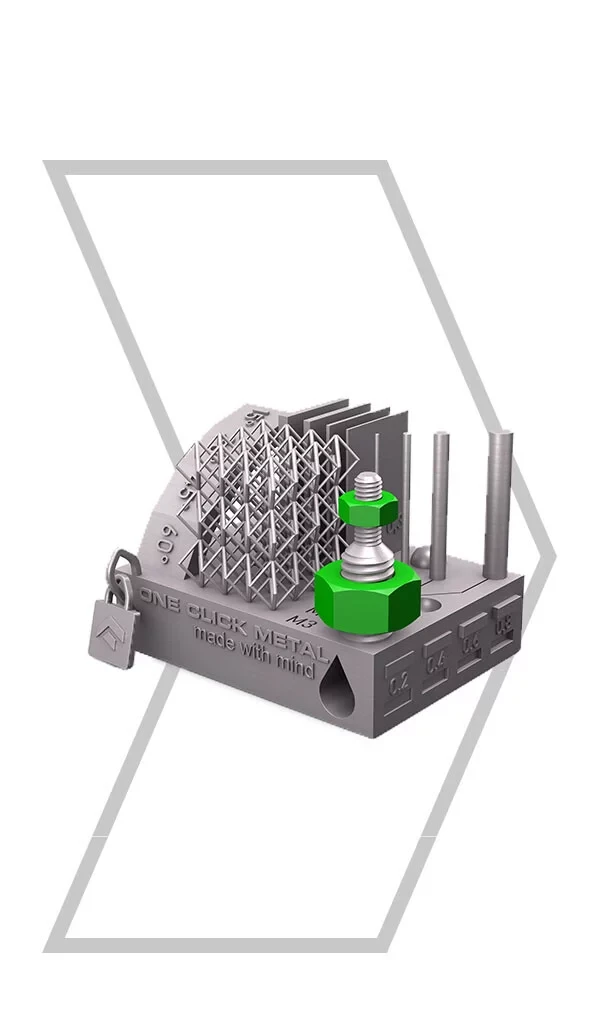

One Click Metal. The affordable and easy way to use metal 3d printing, without compromising on process robustness and part quality.

One Click Metal solves your problems in metal additive manufacturing and helps you to get access to metal 3D printing technology.

Applications

– Product development

– Prototyping

– Industrial production of individual parts, small or large series

– Research and development

– Education

Introducing the BOLDseries

With our product solutions to a holistic process chain

Our metal 3D printing system BOLDseries

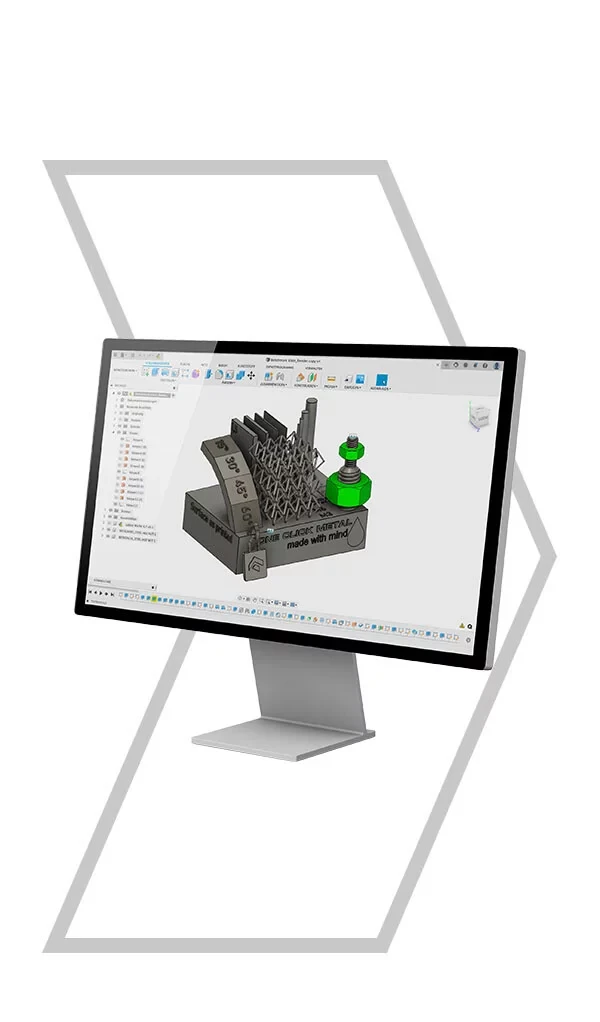

MPREP The data preparation software. Easy to use, Data preparation is completed in just four steps

- Load, place & align part.

- Generate & adjust supports

- Assign parameters

- Slice in layers & load to machine

MONE The digital platform for remote monitoring and control

- Remote Monitoring and control

- Machine overview

- Status Update

MPRINT+ The metal 3D printer

- 200W fiber laser

- Large build volume of 150mm x 150mm x 150mm.

- 70 µm focus diameter

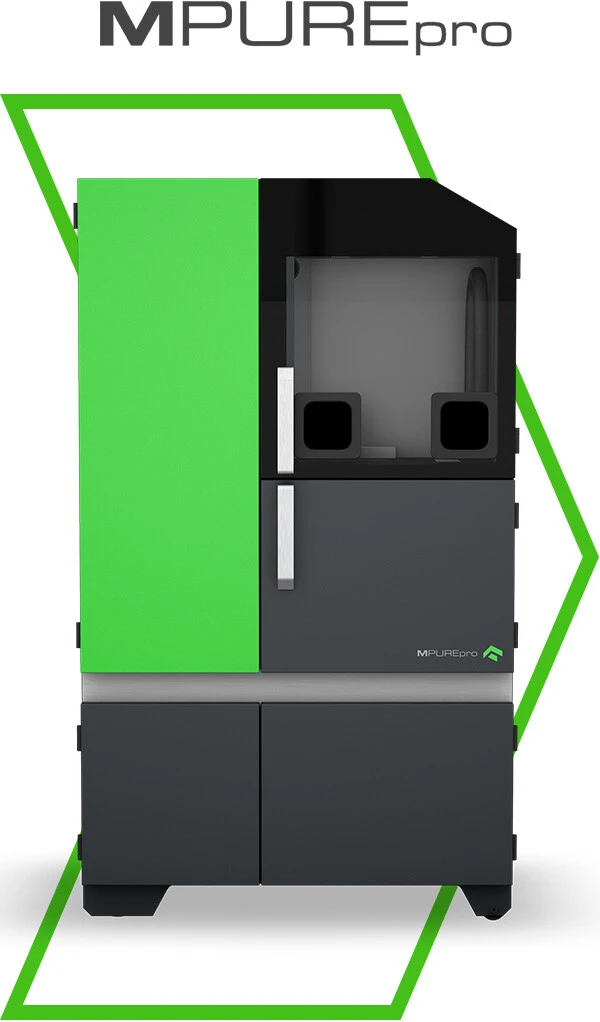

MPUREpro The problem of unsafe and unclean powder management is solved with the BOLDSERIES by the cartridge system.

- Separation of supply and overflow cartridges avoid risk of mix-ups.

- Direct powder contact for the user is significantly reduced.

- Most of the processed powder can be reused

Material

Stainless Steel 1.4404 และ 316L

Properties

- Good corrosion resistance

- High tensile strength

- Good strength and rigidity

- Heat resistant

- No rust

Aluminum 3.2382

Properties

- High strength, but not as high as steel, and is much lighter in weight than steel.

- High dynamic load capacity

- Easily post-processing possible

Tool Steel 1.2709

Properties

- thermally hardenable up to approx. 54 HRC

- good thermal conductivity compared to other steels

One Click Metal BOLDseries Specifications

You know the struggle with open metal powder everywhere and the whole powder management is neither clean nor very safe?

Let us introduce you to the powder circulation of the BOLDseries: all powder necessary for the printing process comes in powder cartridges. They minimize direct powder contact for the user and at the same time enable a sustainable recycling process. With two different cartridges – a supply cartridge and an overflow cartridge – possible mistakes like mixing the processed powder with fresh or recycled powder are avoided. So fewer risks and more success with the powder management of our BOLDseries.

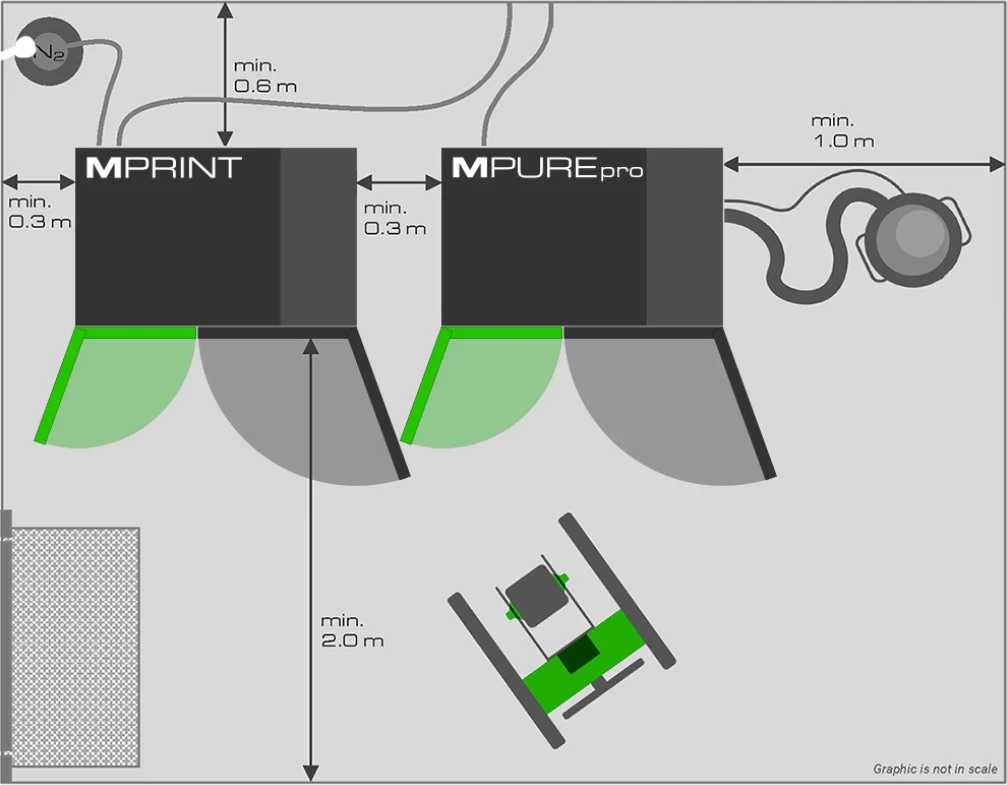

MPRINT

Powder Supply

Process chamber

Build module

Replaceable safe gas filter

Connection and consumption

Dimensions and weight

MPUREpro

Unpacking chamber

Sieving unit for powder recycling

Connection and consumption

Dimensions and weight

Installation conditions (Recommendation/Best Practice)

One Click Metal BOLDseries powder management & powder circulation | Metal 3D Printing