GOM ScanCobot

“Metrology-Grade Automation at an Affordable Price”

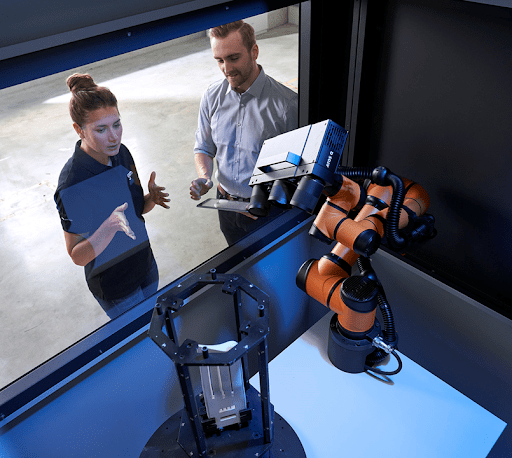

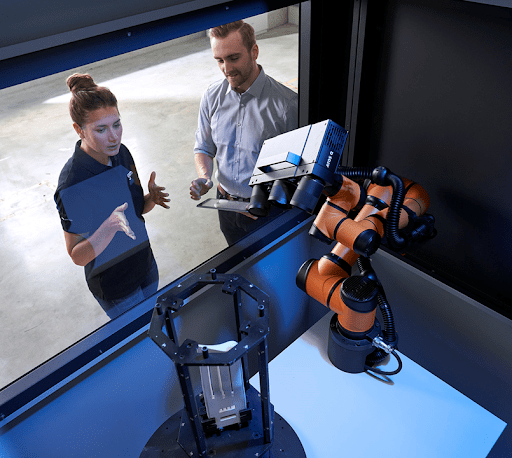

The GOM ScanCobot (Collaborative Robots) is a mobile automated 3D scanning system that combines the precise optical ATOS Q 3D scanner with a collaborative robot and a motorized rotation table. The system ensures high-precision measurement of small and medium-sized parts and tools weighing up to 50 kg.

With the high-precision quality of ATOS combined with an automated robotic arm, the GOM ScanCobot is a cost-effective, easy-to-use automated 3D scanning solution.

GOM ScanCobot 3D Scanner

Fast track to automated metrology.

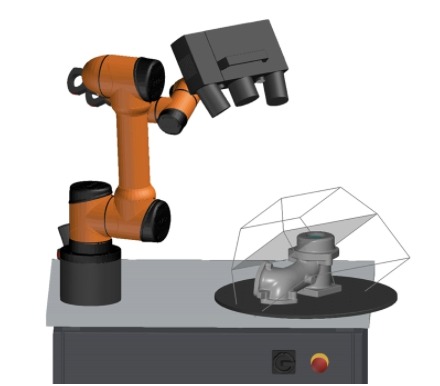

Easy Robot Programming in the Virtual Measuring Room – perfect combination for simple automated inspection tasks. The mobile GOM ScanCobot excels by its small footprint and is ideal for efficient quality control of small and medium-sized parts.

Measurement planning, digitizing, and inspection occur in the virtual measuring room (VMR) of the powerful GOM Inspect software. The mobile GOM ScanCobot measuring station is used for efficient scanning and subsequent automated inspection of small and medium-sized parts – thus accelerating processes in quality assurance.

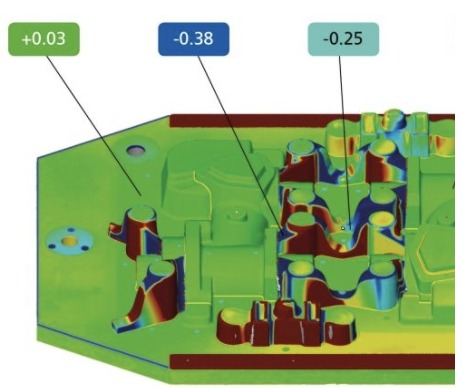

ATOS Q – High-speed 3D scanner with superior data quality generates a complete measurement dataset in a short time from detailed full-field 3D coordinates. Instead of point-based or linear data, the system delivers full-field data about deviations between the actual 3D coordinates and the CAD data.

ATOS Q is available in two different camera resolutions, 12 M and 8 M. The 3D scanners capture up to 2 × 12 million or 2× 8 million coordinate points during scanning. The accuracy, resolution, and measuring area can be defined as desired. Five precision lenses are available, which cover measuring fields of different sizes: 100, 170, 270, 350, 500.

GOM COBOT 3D SCANNER Fast track to automated metrology

Easy Robot Programming in the Virtual Measuring Room – perfect combination for simple automated inspection tasks. The mobile GOM ScanCobot excels by its small footprint and is ideal for efficient quality control of small and medium-sized parts.

Measurement planning, digitizing, and inspection occur in the virtual measuring room (VMR) of the powerful GOM Inspect software. The mobile GOM ScanCobot measuring station is used for efficient scanning and subsequent automated inspection of small and medium-sized parts – thus accelerating processes in quality assurance.

ATOS Q – High-speed 3D scanner with superior data quality generates a complete measurement dataset in a short time from detailed full-field 3D coordinates. Instead of point-based or linear data, the system delivers full-field data about deviations between the actual 3D coordinates and the CAD data.

ATOS Q is available in two different camera resolutions, 12 M and 8 M. The 3D scanners capture up to 2 × 12 million or 2× 8 million coordinate points during scanning. The accuracy, resolution, and measuring area can be defined as desired. Five precision lenses are available, which cover measuring fields of different sizes: 100, 170, 270, 350, 500.

** Contact Us : Tel. 090-198-6321, Email [email protected]

The benefit of GOM ScanCobot

GOM ScanCobot and ATOS Q are a Perfect Match

Easy Programming

- GOM Virtual measuring room

- Smart teach

- No teach pendant usage

Easy Moves & Operation

- Compact, mobile and collaborative

- Move to where it is needed

- Easy startup and operation

Highest Performance

- High-speed fringe projection

- Fast data processing

- High data throughput

Highest Data Quality

- GOM Inspect software for measuring data from the 3D scanner saves you time in furthering your reverse engineering and 3D printing.

- Intelligent Software

Technical Data : GOM ScanCobot

| Dimensions footprint [mm] : 975 x 775 |

| Working height [mm] : 1000 |

| Power supply : Standard, 100–240 V (1-phase, 10A) |

| Max. part size [diameter in mm] : 500 |

| Max. part weight [kg] : 50 |

| System weight : < 185 kg. |

Innovative Cobot 3D Scanner for Inspection

Case Study GOM