Connex3 — Rapid Tooling and Prototyping in Multiple Materials

Objet500 and Objet350 Connex3

Color and multi-material 3D printing

Connex3 was the first 3D printer in the world to simultaneously 3D print multiple colors and materials. Today it remains alone in its class with a broader set of capabilities that amplify its advantages.

Variety and Versatility

Bring agility and aesthetics to every stage of product development and production. Based on PolyJet Technology, Connex3 offers amazing surface smoothness, fine details and the widest range of material properties available in a 3D printer.

A Multitude of Materials

For parts that require a range of mechanical, optical or thermal properties – like non-slip grips, transparent windows, flexible hinges or heat-resistant surfaces – Connex3 can vary material properties within a single print job.

Fast, Flexible Color

Stratasys Creative Colors Software, powered by Adobe 3D Color Print Engine, blends new color capabilities with a hassle-free workflow. Produce smooth three-color gradients and vivid multi-color textures based on the color information in your original CAD file, and/or graphic elements added right in Adobe Photoshop. The software recommends the closest visual match, and provides realistic previews to eliminate the guesswork.

Detail and Realism

Create precise threading or crisp tracking codes directly from CAD. With 16-micron layer resolution, you can see, touch, test and perfect every detail.

Great Throughput

With a spacious build envelope and the ability to vary materials within a single print job, you can pack a tray with assorted parts to power through tool and prototype production.

Efficiency

Spend less time processing parts. PolyJet models are smooth, beautiful and ready to handle without additional curing or post-processing. Soluble support material lets you clean undercuts and internal voids with minimal effort.

Cost Performance

High throughput and an efficient workflow optimize your productivity, so Connex3 achieves a low cost of ownership per part.

Customer success: Trek Bicycle

Designers and engineers at Trek Bicycle were among the first to adopt the Connex3 to create prototypes that look and feel like production parts.

“In order to make the best bikes here at Trek, we need the best tools. And Connex3 is the best tool for the job.”

— Mike Zeigle, Trek

3D Printed on Connex3

Connex3 Materials

Digital ABS in the Mix:

For tough, ergonomic tooling, only the Objet500 Connex3 lets you blend the strongest PolyJet photopolymer, Digital ABS, with Rubber-like Material to produce a range of Shore A values with great durability.

High Temperature:

This material is ideal for tooling and fixtures that require higher heat. Blend with Rubber-like material to achieve a range of Shore A values and thermal properties.

Bio-compatible:

Medical materials offer excellent visualization and great dimensional stability for dental delivery trays, surgical orthopedic guides and hearing aids.

Rubber-like:

With a range of bright and subtle colors, opacities and elastomer characteristics, this adaptable material is ideal for a variety of tools and prototypes.

Simulated Polypropylene:

Tough single-material options withstand the stress of living hinges, flexible closures and snap-fit parts. Combine with Rubber-like material for a range of grayscale shades and Shore A hardness values.

Learn more about the range of PolyJet materials available on the Objet500 Connex3, including Digital ABS, High Temperature, Bio-compatible and Simulated Polypropylene.

Specifications

Single materials:

Vero family of opaque materials, including:

- VeroWhitePlus (RGD835)

- VeroGray (RGD850)

- VeroBlue (RGD840)

- VeroBlackPlus (RGD875)

- VeroCyan

- VeroMagenta

- VeroYellow

- VeroBlack

- VeroWhitePlus (not compatible with Stratasys Creative Colors)

- Vero PureWhite, a brilliant white 20 percent brighter than VeroWhitePlus with twice the opacity

Model materials:

- Vero family of opaque materials, including various neutral shades and vibrant colors

- Tango family rubber-like flexible materials

- Medical: MED610

- Digital ABS and Digital ABS2 in ivory and green

- DurusWhite RGD430

- High Temperature RGD525 white

- Transparent: VeroClear and RGD720

Digital model materials:

Hundreds of composite materials can be manufactured on the fly including:

- Digital ABS

- Rubber-like materials in a variety of Shore A values

- Vibrant blended colors in rigid opaque

- Translucent colored tints

- Polypropylene-like materials with improved thermal resistance

Support material:

SUP705 (WaterJet removable)

SUP706 (soluble)

Net build size:

Objet350 Connex3: 340 × 340 × 200 mm (13.4 × 13.4 × 7.9 in.)

Objet500 Connex3: 490 × 390 × 200 mm (19.3 × 15.4 × 7.9 in.)

Layer thickness:

Horizontal build layers down to 16 microns (.0006 in.)

Print speed:

Printing mode builds parts at 12 mm per hour/strip in 16-micron (0.0006 in.)

Build resolution:

X-axis: 600 dpi; Y-axis: 600 dpi; Z-axis: 1600 dpi

Printing Modes:

- Digital material: 30-micron (0.001 in.) resolution

- High quality: 16-micron (0.0006 in.) resolution

- High speed: 30-micron (0.001 in.) resolution

Accuracy:

20-85 micron for features below 50 mm; up to 200 micron for full model size (for rigid materials only, depending on geometry, build parameters and model orientation)

Input Format:

STL, OBJDF and SLC File

Workstation compatibility:

Windows 7 and Windows 8

Network connectivity:

LAN – TCP/IP

Size and weight:

1400 x 1260 x 1100 mm (55.1 x 49.6 x 43.3 in.)

430 kg (948 lbs)

Material Cabinet:

330 (w) x 1170 (h) x 640 (d) mm

(13 x 46.1 x 26.2 in.)

76 Kg (168 lbs.)

Print heads:

8 units

Power Requirements:

100-120VAC 50/60 Hz; 13.5A 200-240VAC 50/60 Hz; 7A single phase

Operational Environment:

Temperature 18 C-25 C (64 F-77 F); relative humidity 30-70 percent (non-condensing)

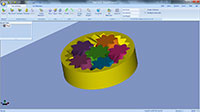

Objet Studio Software

Gear Bearing by Emmett

Objet Studio makes it simple to build high-quality, accurate tooling and prototypes. It transforms STL or WRL files from any 3D CAD application into print-ready 3D models with color, material, and support placement information. With click-and-build wizards, you can quickly edit trays, change materials and colors, manage job queues and perform routine system maintenance.

Objet Studio features:

- Easy tray setup including multiple models and materials

- VRML support for easy color assignment

- Automatic support generation

- On-the-fly slicing so printing can start right away

- Auto-placement of trays for accurate, consistent positioning

- Multi-user networking

Stratasys Creative Colors Software blends new color capabilities with a hassle-free workflow. Now there are more possibilities for realistic, colorful models, and fewer steps from design to print.

3D print directly from Creo CAD software

Take advantage of seamless design-to-3D print workflow with PTC Creo CAD software and the Objet500 Connex3 3D Printer. With this combination you can now print without leaving your PTC Creo CAD software.

In offline mode you can choose a specific Connex3 printer, access its tray size and orient your model for the best build. You can also choose materials, colors and optimize your model’s geometry including checking for proper wall thickness, holes and unclosed surfaces – all in native PTC Creo format.

In online mode you have access to all the features of offline mode plus the ability to query the status of the printer. Check to see which materials and colors are loaded in the printer and if it’s available for use, without the need to use Objet Studio.

With this direct link, PTC Creo CAD software puts part modification at your fingertips.

Find out more at http://www.ptc.com/cad/additive-manufacturing

Top Applications

Learn More

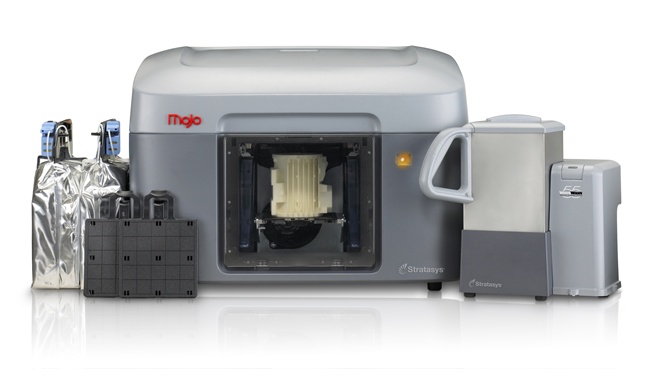

Related Product