A demanding economy is forcing mold makers to be even more creative while facing stiff global competition. Today’s customers insist on precision and durability, while also demanding shorter lead times and lower prices.

SOLIDWORS® product development solutions provide a full range of integrated modeling, simulation, and communication tools that mold, tool, and die manufacturers need to design better products faster—and at lower cost.

Cool Pak LLC

Using the SolidWorks design platform, Cool Pak established its own internal design department to more effectively respond to customer demand for innovative and environmentally friendly packaging solutions.

SUCCESS METRICS

• Cut development cycles by 75 percent

• Moved from design to prototype mold in a single week

• Reduced waste throughout customer supply chains by over 35 percent

• Built an internal design capability

Industry: Mold, Tool & Die

Previous CAD: None

Products(s) Used: SOLIDWORS Standard

Benefit: Collaboration, Ease of Use

VAR: Hawk Ridge Systems

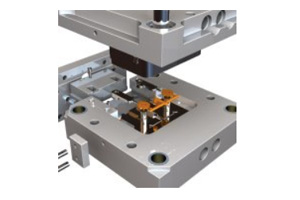

JK Mold Design

JK Mold Design is a leading provider of high-end, complex molds for plastic injection-molded parts and aluminum and zinc die casting.

SUCCESS METRICS

• Shortened product design time by 30-40%

• Reduced errors by 25%

• Cut scrap by 10% by means of CAM integration

Industry: Mold, Tool & Die

Previous CAD: CADKEY

Products(s) Used: SOLIDWORS Office

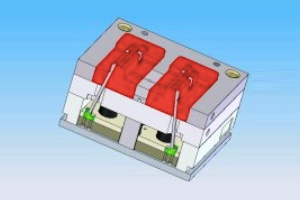

Quality Tooling, Inc.

By using SOLIDWORS CAD software for mold, tool, and die design, Quality Tooling is achieving its goals of increasing throughput and reducing design errors.

SUCCESS METRICS

• Reduced design cycles by 50%

• Eliminated more than 90% of design errors

• Added mold design and draft analysis capabilities

• Improved handling of CAD data

Industry: Mold, Tool & Die

Previous CAD: CADKEY

Products(s) Used: SOLIDWORS Standard

VAR: 3DVision Technologies

Remington Products Company

The productivity gains provided by SOLIDWORS software enabled Remington Products to continue to succeed in the highly competitive, global footwear industry.

SUCCESS METRICS

• Shortened design cycles by 25 percent

• Improved time-to-market by 20 to 25 percent

• Reduced scrap/rework costs by 15 to 20 percent

• Expanded beyond traditional OEM footwear business

Industry: Mold, Tool & Die; Consumer Products

Products(s) Used: SOLIDWORS Professional

Benefit: Value, Ease of Use

VAR: Fisher/Unitech, Inc.